Gripper suits internal and external assembly applications.

Designed to fit O-rings not only to shafts, but also in holes, 6-finger Model ORG 85 features integral stroke and triple jaw sets that move independently from one another. O-ring is first released from first 3 fingers, and then released from last 3 fingers in controlled manner. Clamping width of diameter to be fitted ranges from 5-150 mm. Stroke of 2 sets of triple jaws range from 0-21 mm for...

Read More »

DE-STA-CO to Showcase New, Patented Selection of Automation and Workholding Solutions at ATExpo

Madison Heights, Michigan, July 17, 2006 - DE-STA-CO will feature its entire line of products ranging from manual clamps to automation solutions at this year's Assembly Technology Expo (ATExpo) in booth #611. ATExpo will be held at the Donald E. Stephens Convention Center in Chicago, Illinois from September 26 - 28. The newest product to join DE-STA-CO Robohand's impressive list of automation...

Read More »End Effector Tooling suits material handling applications.

Based upon modular concept with accessories such as automatic tool changers, compliance devices, robotic adapter plates, vacuum cups, and sprue cutters, MET Modular End Effector Tooling System can be reconfigured, re-used, or interchanged with other units. Lightweight aluminum system can be mounted to robot in end-mount cantilever style or mid-mount configuration. It offers 360Ã-

Read More »System facilitates end-effector tool changes.

Model QC-1200 automatic tool changer accommodates different styles of parts on same assembly machine. Modular design options include Device Net Bus module, self-sealing fluid or pneumatic module, 19 pin I/O module, and 200 A weld power module. Integral latch/unlatch sensor signals coupled condition of tool changer. Unit meets demands of robotic resistance welding and material handling...

Read More »

The Top 5 Major Benefits of Using Injection-molded EVA Foam for Designing Products

When considering the type of materials to use for an innovative new product, there are many factors to consider, including material quality, design flexibility, production timelines and costs. Suffice it to say that manufacturers need to strike a delicate balance between performance and profitability.

Read More »

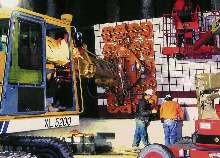

End Effector installs curtain wall where cranes can't fit.

Hydaulically powered 5-Axis End Effector utilizes vacuum connection system for lifting and positioning pre-glazed curtain wall panels and other architectural components weighing up to 3,000 lb. End effector mounts to tangs of most 6,000-10,000 lb variable reach forklifts and uses up to 16 vacuum cups in customizable configurations. Six remote functions enable installers to move panels from...

Read More »

End Effectors target wheel handling operations.

When used with appropriate lifting device, wheel handling end effectors improve operator's ability to lift and position wheels through manufacturing process. Lifting device and end effector have powered functions for lift and grip forces, which minimizes risk of injury to upper body, arms, and hands. Applications include pick/place transfers, loading vertical/horizontal chucks, or rotating wheels...

Read More »

End Effectors grip porous sheet materials with needles.

Operated with 90 psi shop air, SCH20 and SCH23 robotic, pneumatic end effectors utilize 2 sets of needles that extend from gripper at 120Ã-

Read More »

Vacuum End-Effectors bolt onto mobile cranes at job site.

Utilizing foam vacuum pads, custom built Job Site End-Effector Systems bolt onto outdoor mobile cranes and boom extensions to handle tile, concrete, and glass panels that measure up to 10 x 40 ft and weigh up to 10,000 lb. Items are picked up from top surface without slings or blocking, facilitating alignment and installation processes and preventing damage. They employ fully redundant vacuum...

Read More »

Tooling System suits light material handling applications.

Configurable Modular End Effector Tooling System (MET) offers accessories such as automatic tool changers, compliance devices, robotic adapter plates, vacuum cups, and nipper mounts. Made of aluminum, it can be mounted to robot in end-mount cantilever style or mid-mount configuration. Features include 360Ã-

Read More »

Robot End Effectors fix alignment problems.

CV vertical compliance devices detect axial misalignment between two parts during assembly process or loading application. CH horizontal compliance devices work when lateral misalignment is present during assembly or loading application. Units provide lateral and rotational compliance to reduce jamming and misalignment. AU series emergency stop modules protect robots or other equipment from loads...

Read More »

Acoustic and Thermal Solutions for Original Equipment Manufacturers

Technicon's products solve the most complex noise pollution and thermal problems and improve product marketability. Check out the video to learn more.

Read More »