Polyurethane Potting Compound cures in 1 hour.

Designed to cure within 1 hour at room temperature, 20-2183 features 2:1 mix ratio and low viscosity that makes it suitable for use in cable assemblies, potting electronics, molding parts, and encapsulating electronic components. Tough elastomeric material helps assemblies withstand thermal cycling, offers vibration resistance, and imparts low stress on electronic components during cure....

Read More »

Cost Effective Protection for Submersible Components - Urethane Elastomer Series for Underwater and Extreme Weather Applications

The 20-2330 Series of low durometer urethanes, ranging from Shore A 30 to Shore A 90, is perfect for protecting electronic and other components in extreme conditions.Ã- This Series has outstanding resistance to water, good chemical resistance, and provides great electrical insulation.Ã- The products maintain their flexibility over a broad temperature range (from -40Ã-

Read More »

Flexible Epoxy withstands cryogenic conditions.

Serviceable over wide range of 4 K to 250Ã-

Read More »

Epoxy Adhesive encapsulates sensors in harsh environments.

Combining quartz filler and amine compound, Supreme 45HTQ is suited for bonding and encapsulating transducers, gauges, actuators, and sensors in harsh environments. Epoxy adhesive features tensile strength exceeding 8,500 psi and compressive strength greater than 20,000 psi. Resistant to chemicals, acids, oils, water, and steam, product can withstand long term exposure to 400-500Ã-

Read More »

Grips and Handles - Providing a Strong and Comfortable Grip

To learn more about the different types of Grip and Handle options available or which to select for your specific application, download our product guide.

Read More »

Color Masterbatches target wire and cable industry.

Suited for coloring complex melt processable fluoropolymer resins used as plenum space jacketing materials, MPFP Color Masterbatches come in 10 color-coding formulations matched to Munsell and RAL standards. Products are available in FEP and PVDF resin systems and are expandable to include other MPFP resins as needed. They maintain inherent flame retardancy and low smoke emissions that allow...

Read More »Process Technology Offers Ceramacast 675 High Temperature Potting Compound

Process Technology, manufacturer of electric immersion heaters, inline heaters, heat exchangers and temperature controls, is now offering Ceramacast 675 for over 70% below reail value. Ceramacast 675 is a high temperature, thermally conductive, aluminum nitride filled ceramic potting compound. It is used in the production of quick response sensors such as thermocouples and resistance temperature...

Read More »

Potting Compound withstands temperature extremes.

With thermal conductivity of 25 BTU-in./hr-ft2-Ã-

Read More »

Ceramic Adhesive suits high temperature potting applications.

Magnesium oxide filled, water based, 2-part ceramic adhesive and coating system Ceramabond(TM) 672 can be used in assembly of high temperature catalytic converters for applications to 2,800Ã-

Read More »

Silicone Potting Compound assures complete fill-in.

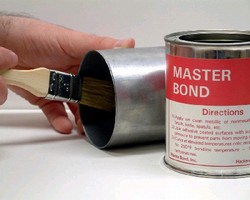

Suitable for casting, potting, and encapsulation, 2-component MasterSil 151 cures at room temperature or more rapidly at elevated temperatures. It features elongation at break of 160%, Shore A hardness of 45, and dielectric strength of 460 V/mil. Optically clear product offers resistance to vibration, impact, shock, and thermal cycling. With service operating temperature range of -65 to +400Ã-

Read More »

Potting Compound has flexible, low-viscosity formulation.

Able to be used in thick and thin cross sections, EP30FL epoxy potting and encapsulation compound is 100% reactive and does not contain any volatiles. It cures at room temperature with minimal shrinkage and adheres to similar as well as dissimilar substrates. Recommended for use in environments exposed to thermal cycling, solution can withstand mechanical shock and vibration. Hardened compound...

Read More »

Triad WAU Wall Plug-In AC Power Supply May Be First To Meet Level VI Energy Efficiency Standard

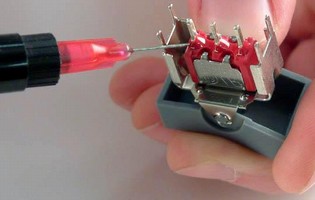

Triad Magnetics, an industry leader and one of the most trusted names in transformer design and manufacturing, is proud to announce the release of the Triad WAU Wall Plug-In AC Power Supply. Engineered to provide robust performance and high reliability, it is setting the standard for 120V/60Hz power supplies. See our video to learn all about it.

Read More »