ExxonMobil and QuestAir Technologies Address Increased Hydrogen Needs in the Refining Industry

FAIRFAX, Va. & BURNABY, B.C.-May 2, 2006-ExxonMobil Research and Engineering Company ( EMRE ) and QuestAir Technologies Inc. (AIM:QAR) (TSX:QAR) announced today that they have signed an agreement to jointly market a novel, large capacity hydrogen purifier as a compact solution for hydrogen recovery in the oil refining industry. QuestAir has been working with EMRE since 2003 to develop this...

Read More »

Wheel Dryer simultaneously dries and regenerates desiccant.

Capable of throughputs from 100-400 lb/hr, NovaWheel(TM) rotating wheel dryer continuously puts dry desiccant into service while regenerating saturated desiccant in same rotational cycle. Use of steel link drive chain to drive desiccant wheel minimizes dew point variation. Cylindrical wheel contains desiccant-impregnated honeycomb divided into 3 sections for moisture removal, purge, and...

Read More »

Perma Pure Showcases Sample Conditioning Solutions at ISA Expo

Toms River, NJ (August 30, 2006) - Perma Pure LLC will exhibit its gas conditioning products at the Instrumentation, Systems and Automation Society (ISA) Expo 2006, booth number 2535. The company offers a full line of dryers, filters, and complete gas sampling systems for use in industrial and scientific applications. The Expo takes place October 17-19 at the Reliant Center, Houston Texas. With...

Read More »Gas Dryers handle flows up to 1 lpm.

Designed to dry hot, wet, sample gases prior to analysis, MDH(TM) Series combines heating element with NafionÃ-® technology, which selectively removes only water from sample gases, leaving rest of gas sample unaffected. Dryers remove water directly from vapor phase, preventing loss of water-soluble gases through dissolution in condensate. Units can dry gases with as much as 30% water by...

Read More »

The Definitive Guide to High-Capacity Autonomous Mobile Robots

This white paper is a complete guide to understanding autonomous mobile robots and their crucial role in various types of material handling applications.

Read More »

Hybrid Cleaning System handles large, heavy product.

Single-chamber, closed-loop regenerative system, Model X-40F combines capabilities of X-Series multi-solvent cleaning system and Mega(TM) series cleaners. System enables wash, rinse, and dry cycle automation in one chamber with minimized dragout or cross-contamination. Rinse solvent is recycled and cleaned ionically after each cycle. Featuring counter-rotating spray wand technology, system...

Read More »

Tank Vent Dryers prevent moisture condensation damage.

Brownell tank vent dryers and adsorbents keep fluids from becoming contaminated by harmful moisture condensation and prevent release of toxic vapors from tank into atmosphere. Sight window allows users to view color change indicator, which signals when adsorbent is saturated and requires replacement or reactivation. Products, used for storage tanks with capacities up to 500,000 L, install with...

Read More »

Heated Module prevents condensation in sample conditioning.

GASS(TM)-Module transforms wet, hot, and dirty stack gases into cool, dry, clean gas samples for emissions monitoring. Able to be integrated into environmental analysis systems, product employs NafionÃ-® membrane dryers that remove water, acid mist, and particulate directly from vapor phase. Drying is continuous, self-regenerating process, with all control deferred to central system. Module...

Read More »

Heated Gas Dryers handle gas flows up to 1.5 Lpm.

Series MD(TM) Dryers combine NafionÃ-® technology with heating element to dry hot, wet, sample gases prior to analysis. Nafion technology selectively removes only water from samples gases, leaving rest of gas sample unaffected. Dryers remove water directly from vapor phase, preventing loss of water-soluble gases through dissolution in condensate. Available for use with 110 or 220 Vac, or 12...

Read More »

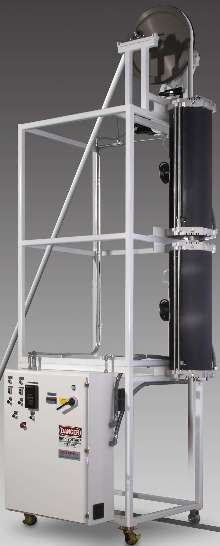

IR Curing Tower improves manufacturing of medical tubing.

Infrared tower uses 2 Radround(TM) short wave IR heaters and drive system to cure silicone tubing at adjustable rates. Heaters have clamshell design and consist of rapid-response T3 lamps. Focused, 91.2 kW IR heat ensures tubing reaches green strength. Ready for product processing almost immediately on power-up, it cools fast enough so that product is not damaged when line stops. Parabolic...

Read More »

Desiccant Dryers offer capacities from 138-594 cfm.

Heatless, twin tower CD65-280 dryers operate up to 232 psig with pressure dewpoints of -40 or -100Ã-

Read More »

Optimize Your Storage or Distribution Facility with Steel King Rack Solutions

Steel King racks are designed to meet seismic requirements in the most demanding conditions. Our durable storage products help your company save on maintenance costs. Check out our product video or download our Rack Planning eBook to learn more.

Read More »