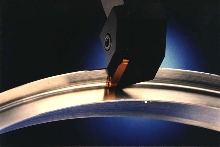

Inserts handle high temperature alloys and iron.

New products include wiper geometry PVD milling and turning inserts; M750 Milling System for malleable and cast irons; SV209 and VC949 coated carbide grades for turning titanium, titanium alloys, and nickel and cobalt based alloys; and APET high shear PCVD coated TPC25 carbide inserts for stainless and high temperature alloys. PVD coated SpectraTurn(TM) and SpecraMill(TM) inserts are coated with...

Read More »

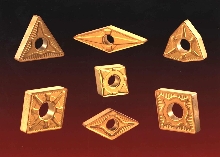

Coated Carbide Inserts can turn tough alloys.

Carbide cutting tool inserts handle high temperature alloys. SV209 has micro-grain carbide substrate with multi-layer CVD coating, while VC949 has aluminum titanium nitride PVD coating over micro-grain carbide substrate. SV209 can turn chrome cobalt alloys, inconels, hastelloys, stellites, and stainless steels. VC949 can turn titanium and titanium alloys. Both grades are available in LM...

Read More »Inserts feature tip geometry that doubles tool's life.

Inserts are designed for use with ALORIS/YESTOOL line of Quick Tip Indexable Single Carbide Insert Drills. Insert life is doubled in 300 series stainless steel applications at rates of 160 sfm. Inserts are also recommended for use in Titatnium and Inconel. Sizes range from 8.0 to 50.8 mm in .1 mm increments. Drill bodies are available in flute lengths of 3x, 5x, and 7x length to diameter, and...

Read More »

Inserts increase milling productivity.

X500 milling grade inserts are suitable for machining PH stainless steels, high-temperature alloys, titanium, and alpha and beta titanium alloys, as well as iron, cobalt, and nickel-based metals. Substrate and coating combination increases transverse rupture strength up to 25% with improved thermal stability, providing faster cutting feed rates and increasing parts per edge. In one application,...

Read More »

Electric Aviation and a Sustainable Future

This white paper provides an in-depth overview into electric aviation and a sustainable future.

Read More »

Cutting Tool Inserts last 40% longer than before.

CoroCut(R) parting and grooving tools provide good surface finish and have 20 to 40% longer tool life than previous tools. They withstand high axial cutting forces, maximize feed without vibration, and work on materials ranging from aluminum to hardened steels and heat resistant super alloys (HRSAs). Tools are available in Grade H10 carbide, in PVD-TiAIN coated carbide grades, and in four...

Read More »

Inserts combine grooving and turning.

GROOVE 'N TURN(TM) inserts are available in 2 sub-micron grain carbide grades, DM-2(R) for steel and interrupted cutting, and DM-5(R) for aluminum and other non-ferrous alloys. Groove width sizes include .020, .030, .040, .060, .080, .100, and .125 in. with either sharp corners or .007 in. corner radius. Uncoated and TiN coated inserts are in stock. TiCN, TiAIN and diamond coatings are also...

Read More »

Ceramic Insert Grade works with cast iron.

Fine-grain, silicon-nitride Quantum Q60 is formulated for high-speed rough turning and both rough and finish milling of cast irons. Speeds range from 1000 to 3800 sfm depending on depth of cut. Q60 is available in all types of turning and milling geometries. For finish turning, wiper radius insert geometry is available.

Read More »Ceramic Cutters cut faster than carbide.

Kyon 2100 grade silicon nitride based ceramic inserts boost productivity 100% to 500% on high temperature alloys by machining at cutting speeds of 3,000 sfm, 10 to 25 times faster than carbide grades. It performs rough milling of nickel, cobalt, and iron based heat resistant alloys, and rough machining of high temperature alloys such as Waspalloy, Haynes 25, Inconel 718, Stellite, and similar...

Read More »Ceramic Inserts triple cast iron milling productivity.

Fix Perfect ceramic inserts have 8 true cutting edges and run 3 times faster in cast iron milling operations than conventional carbide inserts. Inserts are made of Kyon3500 ceramic that has shock resistance needed to perform roughing operations on cast iron at very high speeds, chiploads, and depths of cut. On-edge or tangentially mounted insert puts 1/2 in. of carbide behind cutting edge of 0.5...

Read More »

Turning Inserts machine all types of steel.

P Series double sided turning inserts are available in 3 grades, 3 styles of chipbreaker geometries, and coated with multi-layer PVD coating for machining steel, cast steel, steel alloys, stainless steel and other long chipping materials. Grades include: AN 3015, which resists flank wear and plastic deformation; AN 3025, for general purpose applications; and AN 3035 with wear resistance for...

Read More »

Solder Redefined

Indium Corporation has developed a new twist on traditional solder by developing a composite with a reinforced matrix internal structure. The result is a solder with increased strength and reliability. Check out this video to learn more about the mechanics behind the groundbreaking technology.

Read More »