REGO-FIX-® Showcasing a Variety of Toolholding Solutions at AeroDef Manufacturing 2011

Indianapolis, Indiana - REGO-FIXÃ-® will be showcasing a variety of new toolholding products at AeroDef Manufacturing 2011, including multiple additions to its innovative powRgripÃ-® toolholding system. REGO-FIX will be displaying products in booth #1254 at the event, which will take place on April 5 - 7 at the Anaheim Convention Center in Anaheim, California. Through its unique approach...

Read More »Kennametal Receives Carnegie Science Center Award for Beyond Blast(TM) Technology

LATROBE, Pa., - Kennametal Inc. (NYSE: KMT) has announced that its revolutionary Beyond Blast metalcutting technology has been honored with a 2011 Carnegie Science Center Award in the category of Advanced Manufacturing. The Carnegie Science Center established the awards program in 1997 to recognize and promote outstanding science and technology achievements in Western Pennsylvania. With this...

Read More »

Coolant System monitors volume and mix ratios.

Mounted to machine coolant tank, Coolant Control Center (CCC) provides continuous real time in-line monitoring of coolant, measuring coolant concentration, PH, conductivity, temperature, and volume. System features PLC for coolant correction and programming routines for precise maintenance of machining fluids. Measuring 16.92 x 38.89 x 11.92 in., CCC has Ã-¾ in. water inlet union and works...

Read More »Soluble Oil Coolant is environmentally friendly.

Chlorine-free, low-foam TRIMÃ-® VHPÃ-® E812 is suited for vertical and horizontal machining centers equipped with high-pressure, through-the-tool coolant delivery systems as well as centerless, cylindrical, and creep feed grinding of ferrous and non-ferrous metals. Product does not foam while still keeping machine clean, rapidly wetting chips and tools to prevent corrosion.

Read More »

Elastomer Shlastomer, Right? Selecting the Right Elastomer for Your Sealing Boots and Fasteners

Different elastomer formulations affect your parts' physical properties, functions, and service life. Therefore, it's important to test a few different elastomers, when assembling your product, to determine the best one for your needs.

Read More »

Coolant Delivery System provides automatic filtration.

Capable of removing particles down to 25 microns from emulsions and oils, Turbo Force coolant delivery system automatically back-flushes contaminants into chip conveyor for individual machines or through central filtration system for multiple station operations. Available with pumps offering flow rates of 1-180 gpm at up to 1,750 psi, system is designed for high-volume, high-pressure applications...

Read More »

Coolant Pump features silicon carbide housing.

Available in 6 sizes, Knoll triple screw pump is capable of volumes up to 180 gpm and pressures to 1,750 psi. Pump is available as pump/motor package or as complete high pressure system including control valves, reservoir tank, and integral automatic filter.

Read More »

Coolant Delivery System uses ultrasonic cooling nozzles.

To facilitate grinding, Megasonic Cooling System uses highly accelerated and focused coolant streams produced by vibration transducer of megahertz order placed in nozzle. Resulting permeability and vibration acceleration removes fine particles. System is suited for grinding of hard materials, such as LCD glass-edge polishing and super-hard metals. Optional sacrificial front nozzle, made of soft...

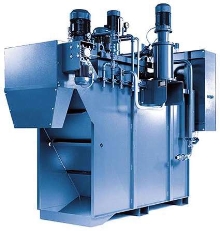

Read More »Processing Machine incorporates several process phases.

XINC eliminates need for multiple machines to handle cleaning, filtration, and moisture elimination processes. After machining process, components are passed through XINC machine, where high velocity blower and air knife strip machining chips and coolant from parts at speeds up to 500 mph. Process air is removed, with coolant sent to filtration unit, while chips are sent for processing to...

Read More »

Complete Water Solutions Offers Wide Range of Water Treatment Equipment

Complete Water Solutions provides full installation tailored to your water treatment needs. Check out the video to learn more.

Read More »