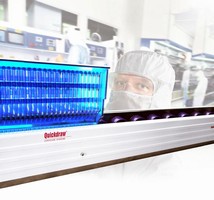

Conveyor System is designed for use in cleanrooms.

QuickdrawÃ-® Conveyor System features Zone BufferingÃ-® and IntellizoneÃ-® technology that utilizes integrated sensors to provide conveyor control within specific conveyor zones. Control system is self-contained with plug-and-go operation. Conveyor design allows for variable speed bi-directional transport, changeable layouts, and precision stopping for tight tolerance processing....

Read More »

Roller Conveyor System provides abrasive blasting.

Designed for in-line surface preparation of long profiles, rod, bar, and tube materials, Model RC-800 can be used with variety of grit, shot, and bead media to produce different surface textures or finishes. Powered rubber rollers at entry and exit sides of blast cabinet grasp work and steadily feed it at controlled and adjustable speed. Inside finishing enclosure, up to 8 suction-blast guns are...

Read More »Defect Removal System targets potato processing industry.

Designed to detect and cut out defects in potato strips at rates to 16,200 lb/hr, ADRÃ-® 5 integrates inspection capabilities of G6 electro-optical platform with modular vision engine and trichromatic cameras. Components include Hi-Res Vis/IR cameras, belt conveyor, rotary cutter, and Iso-FloÃ-® vibratory conveyors, combined to facilitate process of aligning, isolating, inspecting, and...

Read More »

Conveyor handles food processing applications.

Flat-FlexÃ-® Shuttle Conveyor is designed to gap product and turn its direction of travel through 90Ã-

Read More »

Tips for Managing Dangerous Dust in Manufacturing Facilities

This eBook covers important considerations when creating a dust management plan for your facility. For more information, download now.

Read More »

Low-Profile Conveyors from QC Industries Are Ideal for Low-Headroom Applications

Cincinnati, OH - The 125 Series line of conveyors from QC Industries feature a very low profile (1.89 ), allowing these unique conveyors to be used in tight quarters where conventional conveyors will not fit. Belt widths of 2 to 24 are available, in lengths from 4 feet to 12 feet, with load carrying capacity of up to 450 pounds. A unique snap-in sealed tail assembly allows belts to be changed in...

Read More »Material Feed Conveyors offer tramp metal protection.

Available in belt widths from 12-60 in., Grinder/Shredder Feed Conveyors catch ferrous and nonferrous metal contaminants in conveyed material before they damage grinders or ruin product. They may be combined with any of 3 Bunting Metal Detectors that sense all conductive metals and have self-diagnostics for adjustable operation; all metal detectors have Product-Effect Compensation and EMI/RFI...

Read More »Magnetic Conveyor handles ferrous and non-ferrous chips.

Magna-ToteÃ-® incorporates stationary magnetic bed plate as well as conveyor with stainless steel scraper function and standard bed-style conveyance. Unit separates ferrous chip materials from coolants and conveys both ferrous chips and small non-ferrous particles. In addition to dual recovery method for optimal coolant recovery, conveyor features roller chain configuration and...

Read More »Magnetic Chip and Parts Conveyors handle abrasive materials.

Beltless MagSlide(TM) Chip and Parts Conveyors remove, transport, and elevate abrasive or oily ferrous parts, jagged scrap, and other materials that can jam or damage conventional belt conveyors. Permanently lubricated twin-roller drive chains that hold and move conveyor magnets travel in oil-impregnated SlideTrack(TM) channels made from ultra-high-molecular-weight polyethylene, providing...

Read More »End-to-End Tissue Handling Solutions from Intralox on Display at Tissue World 2006

Intralox, L.L.C., announced that their latest conveyor solutions for Tissue applications will be on display at Tissue World 2006, March 14-17, in Miami, Florida. Recent product innovations from Intralox have addressed the greatest challenges facing the Tissue Industry. Intralox uses a team-oriented approach to focus on developing a specific solution for every application. As a result, companies...

Read More »Chain Conveyor has ergonomic design for moving small parts.

Designed to convey small parts, assembly components, and fasteners, Part-ToteÃ-® features low-profile, floor-level hopper for ergonomic loading and conveyor that elevates parts to overhead feed hoppers, vibratory bowls, or storage bins. Conveyor is also suited for inter-floor use and has modular design that can be modified to match any application. Conveyor belt consists of articulated...

Read More »

ISO-Certified J&D Tube Benders Delivers Rapid Tubeline Fabrication Services

J&D Tube Benders' laser cutting and machining services provide accurate and complex features on tubes of all shapes and sizes. Check out the video to learn more!

Read More »