New BIO Controllers & Meters Resist to In-line Water Contamination

Features ultrasharp color display which provides at a glance understanding of user processes status. Includes high-speed EtherCAT or EtherNet/IP interfaces option to meet or exceed pharma 4.0 requirements. Ideal for monoclonal antibody production, vaccine production, insulin production and organ/tissue maintenance.

Read More »

New D/3 Version 16.1 DCS Software is Designed to Ease the Addition of Enhanced Functionality

Can be used to simulate any existing configuration without changing the application code. Capable to train personnel and develop, demonstrate, and validate prospective changes without impacting production or safety. Ability to define sequence units without interrupting production.

Read More »

New EM-05 4 Series Electronic Slide Bolt Uses Gear Motor-driven Mechanism

Integrates an electronic lock with latch bolt position sensing and door sensing, allowing for simple monitoring of door and latch status. Features high energy efficiency, requiring no power draw to maintain its retracted or extended position. Installed in tight spaces and is adaptable to various mounting requirements.

Read More »

New maXTouch Touchscreen Controllers are Compatible with maXTouch Studio and Software Development Environment

Available in MXT1067TD, MXT1189TD and MXT1665TD devices. Includes printed circuit board (PCB), touch sensor on a clear glass lens, flat printed circuit (FPC), bridge PCB, cables and software documentation. Support up to equivalence of 4.5 mm polymethyl methacrylate.

Read More »

OPTICS IN THE SEMICONDUCTOR INDUSTRY

This white paper provides an in-depth overview into optics in the semiconductor industry.

Read More »

New Fixed Location and Configurable No-Fly Zone Systems for Personnel and Facility Safety

Fixed location configurations are optimized for two-sided, three-sided or four-sided applications. Configurable No-fly zone systems utilize laser positioning sensors installed on bridge and trolley motions. Incorporates simplified menu-driven operator interface accessed over 2.4 or 5 GHz wireless connection.

Read More »Motion Controller improves high-speed application performance.

CompactLogix 5380 controller supports high-speed applications with up to 20 axes of motion. When combined with Bulletin 5069 Compact I/O system, scheduled outputs improve I/O response time to as fast as 0.2 msec. Event triggers from I/O modules provide near-instantaneous task execution, while dual-configurable, 1-gigabit Ethernet port supports DLR topologies or use of multiple IP addresses....

Read More »

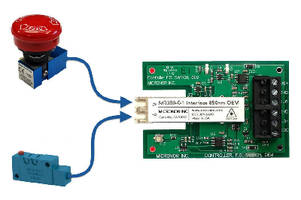

OEM Controller supports fiber optic signaling sensors.

Containing transmitter and optical receiver, which operate over Duplex LC multimode fiber optic link, Model MR380-0 provides turn-key solution for OEMs integrating MR38X series ZapFREEÃ-® Fiber Optic Signaling Sensors into their product. Transmitter sends constant light level via transmit fiber which is interrupted when fiber optic switch activates or sensor beam is broken. Operating from...

Read More »AMAG Technology and March Networks Deliver Integrated IP Video Surveillance and Access Control Solution

OTTAWA and TORRANCE, CA - March NetworksÃ-® and AMAG Technology are pleased to announce the certified integration of the March Networks Command™ Enterprise video management solution with AMAG's Symmetry™ Access Control system. The integration provides organizations with a single, unified IP video surveillance and access control solution that enables better situational awareness, improved...

Read More »

Electronics Chassis Manager provides intelligent control.

IQCM-20 Intelligent Chassis Manager provides diagnostic, management, and control functions for electronic chassis. Supporting VPX, VME, and other types of chassis, stand-off mounted solution features 20 analogÃ- and 8 digital sensors in addition to GUI; fan controls; Ethernet, USB, and/or RS 232 interfaces; and field-upgradable firmware. Capabilities include datalogging, monitoring of up to 8...

Read More »

Automation Torque Control System increases productivity.

WithÃ- digital adjustable torque setting, variable torque and speed control, and multiple I/O options for integration with PLC, SH-Series helps manufacturers optimize assembly area, reduce labor, and increase productivity. WindowsÃ-®-based software allows customization forÃ- each fastening application, andÃ- multiple fastening strategies can be implemented for sensitive or...

Read More »

Standex Engraving Mold-Tech Offers Nickel Shell Capabilities on a Global Scale

Standex Engraving Mold-Tech is the premier, global supplier for mold texturing and surface finishing. With a full range of services, Standex Engraving Mold-Tech is also the only nickel shell supplier producing in three global locations. See our video to learn more.

Read More »