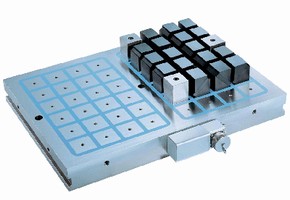

Clamping System utilizes electro-permanent magnets.

With MAGNOS Clamping System, 5-sided machining is possible at high holding forces, without any interfering contours of clamping device. Pole extensions that act as workpiece support allow user to position different workpieces rapidly and precisely. Uniform clamping force is possible due to poles' quadratic geometry. Pole sizes of 50, 75, and 100 mm are available, enabling holding forces to be...

Read More »

Static Clamping System fits in tight spaces.

Featuring compact design, Model SST 60 provides exact position clamping of mechanical components like pallets or workpieces. It offers clamping force of 18 kN, clamping pressure of 80 bar, and release pressure of 50 bar. Attachment options include fixed, one-direction free (during positioning, before clamping) and 2 directions (during positioning, before clamping).

Read More »

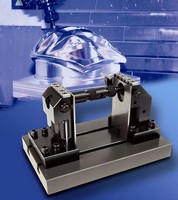

Clamping System is designed for 5-axis machining centers.

Providing up to 40 kN clamping force, Model VB 5 AX 100 allows high speed, continuous 5-axis cutting motion of sculptured surfaces, pockets, and other 3D features in single clamping setup. System eliminates jaw deflection and/or part misalignment during machining operations. Features include clamping width of 2-236 mm, clamping depth of 8 mm, and height above machine table of 175 mm with extended...

Read More »Clamping System offers high-density workholding solution.

MultiChuck MMY Concentric Clamping System provides manual self-centering static workholding solution for machining centers, milling machines, and grinders. Top face operation optimizes number of chucks that can be banked closely together. Available with 2 or 3 jaws, system can be provided as standard in chuck sizes of 80, 100, 125, and 150 mm. It combines fast initial jaw travel with controlled...

Read More »

Introduction to Optical Replication

To learn more about the optical replication process, and how to avoid complications, download this white paper now.

Read More »

HSK Spindles apply 440 lb of clamping force.

Designed for Speroni Models STP-34, STP-35, and Esperia tool presetter machines, Integrated Automatic Mechanical Clamping HSK Spindles are capable of accommodating tooling in sizes of HSK 25 - HSK 80. Tool clamping force seats HSK tooling into tool presetter spindle in similar way as it is drawn into machine tool spindle to provide precision and repeatability.

Read More »

Clamping System offers hydraulic pull cylinder alternative.

Manually operated Speed Block lets operator tighten clamp when drive screw is not accessible; cam-actuated piston moves drive plate up and down, loosening and tightening clamp screw. Used on any clamp that uses straight draw, product is offered in single station suited for clamping pieces over 2 in. in diameter. Mounting holes are pre-machined on 4.125 bolt circle for 3- or 4-hole installation....

Read More »

Press Brake Work Support facilitates press brake job setup.

Twist-in Fast Setup Work Support system aids in setup of press brake jobs that need work support. Featuring quick clamping adjustment handles, product enables work supports to be positioned and clamped without requiring use of wrench. Separate adjustment handle for each axis allows left/right, in/out, and up/down positioning. Features include two 15 in. support arms and modular, 12 in. steel...

Read More »

Clamping System integrates into optical pre-setting device.

Combination of TRIBOS clamping system and Zoller optical tool pre-setting device allows user to pre-set tooling in holder, within microns. Tooling measuring up to 15Ã-¾ in. long, with dia up to 12Ã-½ in., and weighing up to 40 lbs. can be measured on unit. Pre-setter offers accuracy within 0.001 mm on display and within 0.002 mm on concentricity, with repeatability Ã-

Read More »

Thermal Clamping System grips and releases tool shanks.

Using induction heating, EPB EasyShrink(TM) 10 provides shrink grip and release of cutting tool shanks in as fast as 2 sec. Compact, self-contained unit exerts uniform pressure around entire surface of tool shank; one induction heating coil covers tool shank diameter of 1/8-1.25 in. for carbide and heavy metal and Ã-¼-1.25 in. for steel and HSS. Stop rod height setting system facilitates...

Read More »Position Monitoring System indicates tool status.

OTT/JAKOB employs electronic analog sensor, which detects position and allows user to monitor drawbar for performance and wear. Electronic unit, attached to machine controller, transmits data, while system indicates whether tools are clamped, unclamped, or not present. Tool head accuracy and longevity are increased by monitoring cycles and hours, which indicate whether tools are properly held....

Read More »

Dies & Stamping Services with Over 25 Years of Experience

PDS is an established leader in progressive die stamping, with a reputation for providing precision and value that dates back more than half a century. Through extensive capabilities and a staff of seasoned professionals, we set the standard for quality, delivering flexible services that can meet the needs of the most challenging requirements. See our video to learn more.

Read More »