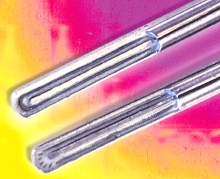

Cartridge Heater suits limited-space applications.

Manufactured with helically wound resistance wire, miniature 1/8 in. FIRERODÃ-® survives higher watt densities without compromising service life. It has 1/8 in. dia and internal thermocouple option for temperature control. Featuring oxidation- and corrosion-resistant sheath, product is offered with crimped-on or swaged-in leads with optional TeflonÃ-® moisture-resistant seals and leads....

Read More »

Swaged Cartridge Heaters suit high-temperature applications.

Suited for applications with temperatures up to 1,500Ã-

Read More »

Cartridge Heaters offer choice of mounting configurations.

Watt-FlexÃ-® Split-Sheath Cartridge Heaters are available with stainless steel flange, mounting bracket, NPT fitting, or puller end plug. Split-sheath construction allows each half of heater to expand independently when energized, for metal-to-metal contact with surrounding bore, maximizing heat transfer. Standard diameters range from 1/4 to 1 in., and 8 to 20 mm. Units come in lengths from 1...

Read More »

Cartridge Heaters offer hot tip option.

Watt-FlexÃ-® Split-Sheath Cartridge Heaters can be constructed to deliver full heat to tip, making them suitable for injection molding applications. Split-sheath construction allows each half of heater to expand independently. Continuous-coil design eliminates cold spots between sections. Standard diameters include 1/4, 3/8, 1/2, 5/8, 11/16, 3/4, and 1 in., as well as 8, 10, 12, 12.5, 15, 16,...

Read More »

Must-Ask Questions When Choosing a Foam Control Agent

This eBook discusses foam controlling agents and how to find the right one for your needs.

Read More »

Cartridge Heaters are available with abrasion protection.

Watt-Flex(R) cartridge heaters have split-sheath construction, which allows each half of heater to expand independently when energized, maximizing metal-to-metal contact with surrounding bore. Continuous-coil design eliminates cold spots between sections, producing uniform temperature profile. Heaters are available in standard dia of 1/4 to 1 in., as well as 8 to 20 mm; in lengths from 1 1/4 to...

Read More »Cartridge Heater warms up small parts.

Small and Mighty 1/8 in. dia cartridge heater can be used to heat small parts, torpedo systems and manifolds. High watt density heater uses 24 to 240 Vac supply voltage, avoiding use of transformers. It has MgO core in 321 stainless steel sheath with hermetically sealed welded end. Options include swaged-in or crimped lead wires in TeflonÃ-® or fiberglass insulation.

Read More »

Krueger Sentry Gauge Announces the Release of Two New Chemical Sight Gauge Models Designed for Aggressive Liquid Storage Monitoring

Krueger Sentry Gauge, a leader in chemical sight gauges, now offers the ultimate in aggressive liquid storage monitoring devices. From sulfuric and hydrochloric acid to bleach, and acetone, our products are designed with robust features that deliver a long and trouble-free service life. See our video to learn all about this new and innovative line of sight gauges.

Read More »