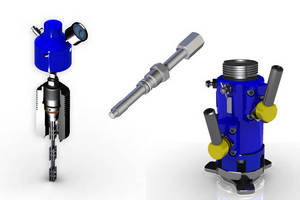

New Cosasco-® High Pressure Retaining Access Equipment Offers and Extra Layer of Protection

Monday, - Rohrback Cosasco released a series of CosascoÃ-® Secondary Process Containment Access Fittings, Probe Adapters, and Double Block and Bleed Service Valve. The high pressure retaining covers and probe adapters are rated for pressures up to 10,000 psi, offering an additional layer of protection for access under pressure. The high pressure access fitting covers feature a bleed valve to...

Read More »

Heated Deck Panels

Heated Deck Panels: The playbook to how these snow-free walkways work for bridges, sidewalks, and platforms

Read More »

SEALTITE® Fittings and Cord Grips Offer Longer Lasting Protection

Anamet Electrical's 316 Stainless steel SEALTITE® fittings and UL-listed cord grips protect sensitive wiring components from fluids, corrosive contaminations, bumps, and abrasions with a steel core and liquid tight conduit jacket. Check out this video to learn more.

Read More »