Fluid Bed Dryer/Granulator/Coater produces uniform results.

With HDGC Fluid Bed Dryer-Granulator-Coater, all functions can be performed in one product container. HDGC Fluid Bed features Diskjet air distribution plate for thorough, uniform mixing and fluidization of batches. Tangential, high-velocity exit of process air prevents sticking/clogging and container dead zones. When granulating, particle size can be controlled/reproduced by selecting specific...

Read More »

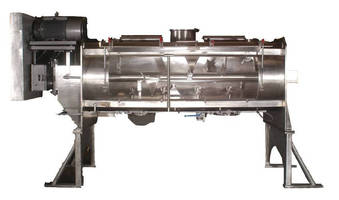

Jacketed Vacuum Dryer has easy-to-clean design.

Horizontal PloughshareÃ-® Jacketed Vacuum Dryer is designed for manufacturers who are concerned with cross contamination from batch to batch in their operation due to allergens, flavors, colors, and formula changes. Full access door across front of jacketed vacuum dryer provides access to perform frequent cleaning operations. Units are capable of taking products from liquids to dry powders.

Read More »First Scientific Comparison of Resin Dryers Shows Why Industry Will Shift to New, More Efficient Drying Systems

As Only Supplier of All Dryer Types, NOVATEC Predicts Major Move from Twin-Bed to Wheel Dryers, Plus Strong Growth for Vacuum and Membrane Systems BALTIMORE, MD, U.S.A., June 18, 2007: Building on its position as the only manufacturer of every type of resin drying system used in the plastics industry, NOVATEC, Inc. recently began scientifically rigorous comparative testing of its drying...

Read More »

New Type of Resin Dryer Eliminates Moving Parts and Desciccant, Cuts Maintenance and Operating Cost, Enhances Part Quality

Unique, Commercially Proven MaguireÃ-® NovaDrier(TM) Compressed Air / Membrane System Will Make European Debut at Maguire Europe Exhibit during K-2007 TAMWORTH, STAFFORDSHIRE, UK, June 27, 2007: Highlighting the Maguire Europe exhibit at K-2007 will the introduction to the European marketplace of the world's only compressed air / membrane resin dryer, a system so simple and efficient that it...

Read More »

Steel Yourself: Tariffs Will Increase Volatility of Steel Pipe Prices

To learn more about how these tariffs might affect your business, and how Aquatherm is continuing to help customers keep their competitive edge, download this white paper now.

Read More »

Rotating Wheel Dryer dries resin and regenerates desiccant.

Offered to resin processors as alternative to twin-tower dryers, NovaWheel(TM) Dryer continuously puts dry desiccant into service while regenerating saturated desiccant in same rotational cycle. Models, available for 45-2,270 kg/hr, use steel link drive chain to drive cylindrical wheel, which contains desiccant-impregnated honeycomb divided into 3 sections. Consistent dew point performance is...

Read More »Ultrasonic Spray Dryers target laboratory applications.

Equipped with non-clogging, ultrasonic atomizing nozzle, SonoDry Models 750, 1000, 1500 operate at up to 750, 1,000, and 1,500 ml/hr, respectively. Designed to handle both aqueous and solvent-based liquids, machines use twin cyclone capture system with possible yields exceeding 95%. All include software that allows for recipe storage and data logging of all functions. Fully integrated magnetic...

Read More »

Cylindrical Vacuum Dryers suit chemical process industries.

Providing full vacuum and internal pressure operation, Cylindrical Vacuum Dryers range from 1 to over 500 cu-ft, and can be constructed from variety of materials such as hastelloy and stainless steel. Units feature dimpled and baffled jackets on trough sides and endplates rated to 200 psig. Internal agitation consists of paddle design, set at opposing angles, to insure material being dried is...

Read More »Electric Infrared Dryer Cures Ink on Paper Napkins at 1,400 FPM

Wisconsin Infrared Systems' Model Web/IR/E/2Z-CM10134, an Electric Infrared Web Drying System, was manufactured for the paper industry to dry ink on lightweight paper webs running at 1,400 FPM. This IR oven was specifically designed to dry water-based ink on a paper web which is processed into napkins for the fast food industry. The dryer has two (2) zones of control to provide uniform heat...

Read More »Fluid Bed Processor offers several operational capabilities.

Circular, vibratory fluid bed dryers, coolers, and moisturizers are offered with Air-Lift device that facilitates disassembly, cleaning, and inspection of fluid bed processing chamber. Available on fluid bed processors in diameters from 18-84 in., self-contained system is comprised of circular fluid bed processor, heating/cooling/moisturizing unit, blower, and cyclone separator on one skid....

Read More »Fluid Bed Dryer handles small batches of bulk solids.

Circular Vibratory Fluid Bed Processing System dries batches up to 1 cu-ft at high temperatures. Integrating 18 in. diameter fluid bed processor with heater, blower, cyclone separator and control, self-contained system is ready for connection to material inlet/outlet and power source. At end of each drying cycle, valve at spout of fluid bed chamber opens automatically to evacuate batch. Optional...

Read More »

Precision Fabricating with Over 40 Years of Experience

Quality Sheet Metal specializes in delivering precision, value, and customer service. With a client base that spans many diverse industries and a reputation for excellence that goes back over four decades, our clients know that we can provide the optimal combination of value and flexibility regardless of the challenge. See our video to learn what we can do for you. Through investments in state-of-the-art design, manufacturing, and quality control systems, Quality Sheet Metal remains focused on maintaining a high standard of quality, customer service, and competitive pricing. With an emphasis on customer satisfaction, Quality Sheet Metal is dedicated to establishing long-term partnerships, similar to the ones they currently have with their valued clients. If you're looking for a new partner with extensive capabilities in sheet metal fabricating and finishing, look no further.

Read More »