Mold Release Agent is designed for cultured marble surfaces.

Available in 1 gal containers and 5 gal pails, Mold Release Coating 7512 is formulated specifically for cultured marble vanities and sinks. Use results in quality surface with smooth feel, reflective shine or luster, and natural appearing color variations. Developed under guidance of ISO 9001 Quality Management System to ensure consistency in product quality, solution exhibits facilitated release...

Read More »Honeywell Sells Novel Low-Global-Warming Blowing Agent to European Customers

Product used in energy-saving foam to seal around windows and doors, as well as in foam adhesives and aerosols, meets EU global warming regulatory requirements MORRIS TOWNSHIP, N.J., Oct. 7, 2008 - Honeywell announced today it has begun selling its low-global-warming blowing agent for one-component foam and aerosol applications in Europe. Honeywell launched the product and received clearance from...

Read More »Epoxy Curing Agents target civil engineering market.

Intended for flooring applications, AnquamineÃ-® 721 and 731 feature optimal adhesion to concrete, rapid hardness development, and concrete protection properties. Since they are waterborne, curing agents emit zero VOCs and exhibit low odor. Anquamine 721 is suited for thin film applications such as concrete primers and paints, while Anquamine 731 targets high-film build applications such as...

Read More »Process Aid targets chemical pulping applications.

Dow CorningÃ-® AF-7500 PulpAid Concentrate is high solids emulsion formulated from advanced silicone antifoam compound technologies and complies with FDA and BfR indirect food contact recommendations. Silicone antifoam concentrate is designed for easy dilution with either tap water or demineralized water along with antimicrobial agent to produce stable, low-solids emulsions.

Read More »

The Ultimate Guide to Enclosed Tubular Drag Cable and Disc Conveyors

This whitepaper provides a comprehensive overview of enclosed tubular drag cable and disc conveyors.

Read More »Epoxy Curing Agents withstand difficult environments.

Resistant to corrosion and chemicals, AncamideÃ-® 2634(TM) and 2652 provide formulators with barrier coats for marine, maintenance, and chemical facility environments. Ancamide 2652 polyamide adduct is designed for use with liquid epoxy resins in 2-part, ambient-cured coatings. It delivers overcoatability of up to 3 months. Exhibiting heat, blush, and cathodic disbondment resistance, Ancamide...

Read More »

Mold Release Agent suits automotive interior components.

Specifically formulated for low gloss in-mold-painted applications, water-based Release Coating 7307 optimizes scuff and mar surface characteristics. Molded surfaces have uniform, low gloss appearance over entire surface area along with dry surface feel. Available in 5 gal pails and 55 gal drums, agent is effective at spray outputs up to 180 g/min.

Read More »Coatings aid in mold release processes.

Mold Release Coatings 6944, 7123, and 7153 provide clean mold release for composite friction materials such as automobile and truck brake composite products. Coatings are non-silicone, water based, dilutable concentrates available in 55 gal drums and 275 gal totes.

Read More »

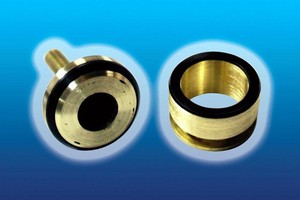

Release Agent improves rubber bonding in molded-metal inserts.

Model EZR324 semi permanent mold release agent provides semi-permanent molded release performance while promoting bonding to molded rubber-metal inserts. Water based agent is suited for EPDM and natural rubber, and is available in 5 gal pails, 55 gal drums, and 275 gal totes.

Read More »

Eraser's Magnet Wire Stripping Pot Offers Clean Stripping of Magnet Wire

The Magnet Wire Stripping Pot strips film insulations from wires of all sizes and configurations. The wires are dipped into the stripping solution to quickly remove the insulation. This stripping method will not cause mechanical stress or abrasion to the conductor. The units are available in two models. The DSP1 has a basic temperature control. The DSP2 has a programmable temperature control for...

Read More »

Solvent strips powder coating masking plugs.

Suited for use on wide range of materials including silicone and neoprene, D-Zolve removes several layers of build-up from self-threading to dual-flanged pull plugs. When used in immersion tank, product's properties lift layers of paint and break chemical bond between powder coating and substrate. Paint layers pull away from surface and fall to bottom of tank.

Read More »

Don't Let Your Money Drain Down the Hole...Drill Steel with Euroboor

As a globally recognized manufacturer of industrial grade portable tools, Euroboor is at the forefront of drilling and cutting technology. Our reputation as an industry leader is built on robust products that fit a wide range of industrial cutting and drilling applications. See our video to learn more about all of our quality products.

Read More »