New HydroFlame Firestop Products Provide Flame, Gas and Liquid Intrusion Protection

UL listed product line includes firestop and acoustic sealants, intumescent wrap strips, pipe collars and putty pads. Offers one-source sleeving and firestop solution for new and retrofit construction. Patented telescoping design that can extend to any deck depth required.

Read More »

New 4K 18Gbps HDMI HDBase-T Extender Supports HDTV Resolutions to 1080p at 120Hz

Transmits uncompressed digital ultra-HD HDMI 4Kx2K 60Hz 4:4:4 signal, IR, RS232, ethernet and power up to 230 feet. Supports ultra-HD 4Kx2K resolutions to 3840x2160 and 4096x2160 at 30/50/60Hz YUV 4:4:4 up to 230 feet. Features ethernet port on the transmitter and receiver for connecting standard network devices such as 100Base-T routers and hubs.

Read More »

Aluminum Foil Tape offers easy-start liner and airtight seal.

With included EasyPEEL™ split liner technology, AF 100 UL 181A-P/B-FX Listed aluminum foil tapeÃ- helps users achieve full system closureÃ- and UL code compliance in HVAC applications. Middle split in liner facilitates and accelerates initial work, even while wearing work gloves, and provides additional stability to tape to help prevent rolling onto itself. Tape supports...

Read More »Interior Adhesives target passenger vehicle applications.

Consisting of one-component, waterborne laminating adhesive, AQUENCEÃ-® PL 5101™ simplifies production by eliminating need to mix components, while curing on-command through heat activation. TECHNOMELTÃ-® AS 8383™, consisting of non-reactive APAO hot melt, offers multi-functional application capabilities, with effectiveness on various substrates, including acrylonitrile butadiene...

Read More »Adhesive Tapes for Energy & Utility Applications

Read about the various types of tapes used in energy and utility applications.

Read More »ECTC is 1 Month Away! Visit Yincae Booth # 506 May 31st to June 3rd

ECTC is 1 MONTH AWAY! VISIT YINCAE BOOTH # 506 May 31st to June 3rd Albany, NY – ECTC is only 1 month away! The tradeshow will take place at The Cosmopolitan hotel in Las Vegas, NV from May 31st to June 3rd. YINCAE hopes that you will stop by our Booth 506 to learn more about YINCAE and the innovative products we have to offer. YINCAE offers a variety of exclusive Adhesives, Thermal Interface,...

Read More »

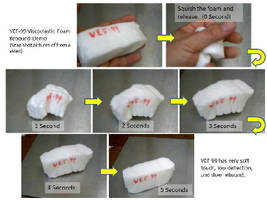

Polyurethane Foam Resin exhibits viscoelastic behavior.

Consisting of liquid polyether based polyurethane, which stays soft at very cold temperatures, VEF-99 Resin creates flexible foam for variety of custom applications. Product has very low deflection when cured and conforms to object with viscoelastic behavior. Pot life is above 30 seconds, which allows small amounts to be batched manually without dispensing machine. With mixing ratio of 1:1 by...

Read More »Lead Paint Sealant and Treatment Formula features low VOCs.

Combining lead treatment reagents, paint penetrators, and water-based paint, Lead DefenderÃ-® provides up to 95% reduction in lead hazards, controls spread of airborne lead dust by up to 99%, and resists acid rain. Low odor, tintable product delivers smooth finish with max adhesion to variety of surfaces. With low VOCs of less than 15 g/L, Lead DefenderÃ-® can be used as All-in-One...

Read More »MBK Offers Green Tape Solutions Helping Heal Our Planet

MBK Tape Solutions Chatsworth, CA – MBK has always been on the forefront of exploring new PSA Pressure Sensitive Adhesive technology, in turn, offering more “green” tape solutions to their broad customer base. Emulsion based, hot melt and UV cured tapes do not omit VOC’s that typical solvent based tapes have in them during their curing/ drying process. The pure nature of how these tapes...

Read More »

Polyurethane Potting Compound cures in 1 hour.

Designed to cure within 1 hour at room temperature, 20-2183 features 2:1 mix ratio and low viscosity that makes it suitable for use in cable assemblies, potting electronics, molding parts, and encapsulating electronic components. Tough elastomeric material helps assemblies withstand thermal cycling, offers vibration resistance, and imparts low stress on electronic components during cure....

Read More »

Versatile TPES for Personal Electronic Devices Provide Wide Range of Properties for Comfort, Durability, and On-The-Go Style

Teknor Apex Offers a Series of MonpreneÃ-® TPEs for Colorful and Touch-Friendly Earbuds, Cords, Grips, Cases, Wristbands, and Other Consumer Electronic Components PAWTUCKET, RI, U.S.A.Ã- – A versatile series of TPEs developed by Teknor Apex Company for consumer electronics provides the enhanced functionality, pleasing tactile properties, vivid color, and durability that are particularly...

Read More »

DoorKing Releases Advanced Long Range Card Reader System with Frequency Hopping Technology

The DoorKing DKS AVI system is at the cutting edge of automotive security technology and represents a leap forward in engineering innovation. When it comes to long-range passive card readers, we lead the industry and set the standard for quality and performance. To find out why the DoorKing DKS AVI system is taking the automotive security industry by storm, see our video.

Read More »