Y-Strainers handle corrosive and high-purity fluid flows.

Press Release Summary:

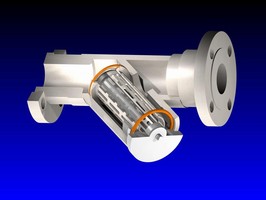

Able to operate in temperatures to 300°F, Kynar® PVDF (polyvinylidene fluoride) Y-strainers protect critical, downstream process equipment from damage and subsequent process down time. Components consist of PVDF housing, PTFE cartridge, Tefzel® ETFE mesh, and FEP-encapsulated o-ring seals. Impervious to UV radiation and hot acids, strainers can be mounted horizontally or vertically and fitted with standard meshes down to 70-micron openings.

Original Press Release:

Introducing Kynar® PVDF Y-Strainers; for Corrosive and High-Purity Fluid Flow at Lower Cost; For Corrosive and High-Purity Fluid Flow at Lower Cost; Available Only from Micromold

Micromold's PVDF Y-strainers handle corrosive and high-purity fluids.

Jan. 23, '07, Yonkers, NY -- Constructed entirely of fluoropolymers, Kynar® PVDF (polyvinylidene fluoride) Y-strainers are now available exclusively from Micromold Products, Inc. for the chemical process industries, especially pharmaceuticals, semiconductors and water treatment, to protect critical, expensive, downstream process equipment from damage, and to reduce process down time.

The strainer materials handle demanding applications including high purity and highly corrosive fluids at operating temperatures up to 300˚F (150˚C). Plastic strainers previously available were not able to handle corrosive materials such as halogens and many acids, or temperatures exceeding 220˚F (105˚C). These PVDF strainers are also impervious to UV radiation, and all materials used are FDA compliant. They also have high rigidity and resistance to creep under mechanical loads.

Strainer components consist of a PVDF housing, PTFE cartridge, Tefzel® ETFE mesh, and FEP-encapsulated o-ring seals. These fluoroploymers far outlast the PVC, CPVC, polypropylene and acetal materials of the most common plastic strainers. And the strainers cost less than those made of exotic metals.

With their low extractable values, PVDF Y-Strainers are especially well suited for semiconductor applications. They have also found use in electropolishing operations, especially in the medical equipment manufacturing industry. With their resistance to radiation and hot acids, they can also handle nuclear waste processing.

Maintenance is simple with their easily removable cartridges. The cartridges are fitted with a range of standard meshes down to 70-micron openings (160 Mesh). For even finer filtration, porous membranes can be used. To minimize flow restriction, open area of the screen for common mesh sizes is at least twice the flow area of the corresponding pipe size.

Standard connections include NPT, socket weld, flanged, and other connections. Strainers can be mounted horizontally or vertically. A drain plug is conveniently located in the removable cartridge cap.

Micromold also custom-manufactures PTFE Y-strainers as well as both PVDF and PTFE basket strainers. For further information, see www.micromold.com and contact Micromold Products, Inc., Dept. TR1, Yonkers, NY 914-969-2850.

Micromold Products, Inc. manufactures a broad line of fluid flow equipment - including pipe, tube and fittings; valves; strainers; spacers, flanges and gaskets; reaction vessel accessories; and tanks -- in many high-performance plastics including PTFE, PVDF, PFA, FEP, polypropylene, PEEK, nylon, PCTFE and UHMW polyethylene. In business since 1950, the company sells worldwide, primarily through distributors.

Kynar® is a registered TM of Arkema, Inc. Tefzel® is a registered TM of DuPont.