Xyntek OEE Solution Addresses Root Cause Issues

YARDLEY, Pa. - A major lifestyle and consumer products manufacturer utilizes Xyntek's OEE manufacturing and packaging solution to improve operational performance and identify the root causes of downtime issues at their production facility.

Benjamin Franklin was famously quoted as saying, "Time is Money" and in the manufacturing and packaging world this statement could not be truer. For many manufacturers and packagers each minute of line downtime during production correlates to significant losses of revenue. In the 1960's Seiichi Nakajima created an algorithm for calculating Overall Equipment Efficiency (OEE) to improve the processes and reduce lost time. Today, Xyntek has taken Mr. Nakajima's vision to the next step with the Xyntek OEE Solution.

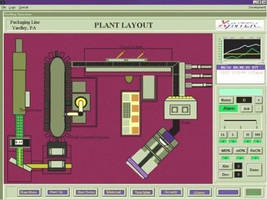

OEE looks at three main factors: Availability of the equipment, Performance of the Equipment, and Quality of the product produced. In order to quantify these factors, data needs to be captured from the equipment, but data alone does not give the full scope of OEE. The Xyntek OEE Solution uses the data from the equipment and line to automatically generate OEE Reports to help determine the root causes of the efficiency drops. The Xyntek OEE Solution is capable of using manual and/or automated data capturing to generate automatic reports of the line OEE. Clients using the Xyntek OEE Solution have found that these reports can help increase production, reduce operational and scrap costs, improve overall quality of the products produced, and efficiency of the lines.

The Xyntek OEE Solution package is available as both a web and application based platform, which can be accessed from any intranet computer or associated smart devices. It provides the user with both real time and historian data / reporting, allowing the user to see live metrics of production OEE and produce reports based on many searchable fields, such as: Lines, Dates/Timeline, Work Cells, Alarm Conditions, Event Summary, Event Severity, Throughput, Quality, and many more.

One key challenge in capturing data automatically for OEE is that not all equipment on a line is capable of outputting the data necessary for OEE, and often many companies are still relying on legacy pieces of equipment, which do not support modern communication protocols at all. In addition to the Xyntek OEE Solution software package, Xyntek is proud to be able to offer our turnkey services for upgrading manufacturing and packaging equipment to work with the OEE Solution.

Mac Hashemian, P.E. Xyntek CEO, explains, "The implementation of the Xyntek OEE Solution does not simply provide our clients with additional information, but gives them a true return on their investment by actively aiding them in improving their line throughput, efficiency, and preemptive maintenance activities. It is Xyntek's goal to empower our clients with the tools they need to be as profitable and successful as possible."

About Xyntek

Founded in 1986 by a group of Real-Time Automation System Solution Engineers, Xyntek, Inc. is a Global Leader in Real-Time IT and Industrial Automation solutions and continues to be one of Philadelphia's fastest growing consulting, design, and build Real-Time Controls IT software and systems solutions engineering firms.

Xyntek's business is based on providing high-end technical services solutions that allow our customers to maximize the benefits of IT and Automation technologies, while adhering with regulatory mandates. The innovation and creativity that we bring to each client opportunity is based on a combination of industry-specific technical knowledge and business processes. Our real-time turn-key design & implementation services are utilized by the world's top companies looking for an edge in the dynamic and quickly evolving global business & technology environment.

Xyntek Contact:

Elliot O. Abreu

Xyntek, Inc.

215-493-7091

www.xyntekinc.com