Winding System handles fine, delicate materials.

Share:

Press Release Summary:

Featuring both spooler and pay off, table top Model RS100 can be operated from standing or sitting position. Control panel offers digital entry of winding parameters such as package width and material length. Stepper motor provides pitch control with digital readout in .0001 in. or 2.5 micron increments. Speed and tension are managed ultrasonically with non-contact loop detector. By regulating DC drive motors, system is capable of 600 fpm speeds on 6 in. core.

Featuring both spooler and pay off, table top Model RS100 can be operated from standing or sitting position. Control panel offers digital entry of winding parameters such as package width and material length. Stepper motor provides pitch control with digital readout in .0001 in. or 2.5 micron increments. Speed and tension are managed ultrasonically with non-contact loop detector. By regulating DC drive motors, system is capable of 600 fpm speeds on 6 in. core.Original Press Release:

Digitally Controlled Winding System for Optical Fiber, Wire or Capillary Tubing

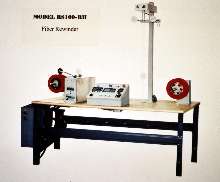

PROGRESSIVE MACHINE CO, INC. introduces our table top Model "RS 100" winding system for fine, delicate materials. This system features both a spooler and pay off. It can be operated from either a standing or sitting position and places such functions as threading, loading, and unloading easily within arms reach to maximize efficiency.

The conveniently placed control panel offers the digital entry of winding parameters such as package width and material length to optimize accuracy and a state of the art stepper motor

provides pitch control with digital readout in .0001" or 2.5 micron increments.

Speed and tension are managed ultrasonically with a non contact loop detector which provides superior control at minimal tension, 10g-75g. By regulating sophisticated DC drive motors, the system is capable of 600 fpm speeds on a 6" core.

The RS100 is an excellenit choice for rewind or breakdown applications and the Model S100 (spooler only) is frequently used for continuous long spooling applications.