Wilmington Machinery to Feature New Medium-Pressure Injection Molding Technology and Blow Molding Machine Options at NPE 2018 Orlando, Florida, Booth #W1823.

Wilmington Machinery of North Carolina will feature the LUMINA MP800 - an alternative to high-pressure injection molding - along with high-speed monolayer and multilayer rotary extrusion blow-molding machines and systems at booth #W1823.

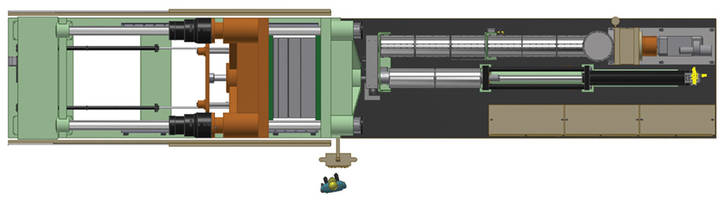

The LUMINA MP800 has a large platen space to tonnage ratio. The two-stage unit has a 152mm extruder with throughputs up to 2,000 pounds per hour, an accumulator shot capacity of 44 pounds, and an injection-pressure capability of 10,000 PSI.

The LUMINA MP800 accepts hot or cold runner molds and processes commodity and engineering grades of thermoplastic materials, including 100 percent recycled materials.

The hybrid design features both a hydraulic press and an electric extruder drive for energy savings, with fast cycle times exceeding all prior designs. The LUMINA MP800 is capable of unlimited applications – automotive, electronics, recreational, enclosures, and much more.

Also featured at NPE, is Wilmington Machinery’s blow- molding machinery. This machinery produces the highest quality containers for a broad range of applications, container sizes and production requirements. Wilmington Machinery’s all electric blow-molding systems have been engineered to exceed capacities, cost and bottle quality previously considered unreachable.

Applications for Wilmington Machinery blow-molding equipment includes: small single serve bottles with production rates up to 1200 bottles per minute, larger handle-ware bottles with production rates up to 200 bottles per minute, and heavy wall 20 liter industrial and automotive containers up to 360 per hour.

Also, learn how Wilmington is capable of testing and conducting research for all packaging and industrial applications from 1-to-6 layers including foaming with nitrogen or CO2 direct gas injection, gas-assist, plus specialty other unique applications.

Since its' founding in 1972, Wilmington Machinery has been building high performance, low-pressure structural foam molding machines. In addition, the company has built custom extrusion, thermoforming, and industrial blow molding machinery, along with a primary line of high capacity rotary blow molding systems for polyolefin monolayer/ multilayer barrier blow molded packaging. From a modern 65,000 SF facility in Wilmington, North Carolina, the company can easily meet any customer's need for extra-large plastics machinery. International shipments can also be arranged through the nearby deep-water Port of Wilmington.

For more information: www.wilmingtonmachinery.com