Welding in a World Of Digitisation

Schweissen & Schneiden 2017 in Düsseldorf (25th – 29th September) will be a chance for Fronius to highlight its focus on digitisation. Challenges and solutions for thermal joining with respect to Industry 4.0 will form a core element of the company’s trade fair stand. Fronius will showcase its digitisation solutions, including the WeldCube data management system, which can be used to gather and analyse welding data. Also on show will be the LaserHybrid welding process, which combines the advantages of laser and MIG processes and can now also be used with the intelligent TPS/i platform. With ArcTig, Fronius presents a TIG solution for mechanised applications that achieves high welding speeds. From its manual welding portfolio, Fronius will introduce the new TIG series, consisting of the MagicWave 190, TransTig 230i and MagicWave 230i, which is ideally suited to the high demands placed on weld-seam quality. The flexible allrounder, the TransSteel 2200, will also wow the crowds. Thanks to its low weight and compatibility with three welding processes, it is up to almost any manual welding challenge. The welding automation team will be presenting the latest generation of MAG welding carriages and orbital welding heads. As well as innovations for robotic, manual, resistance spot and automated welding, Fronius specialists will also be setting aside plenty of time to speak to visitors personally and to address any questions, interests or needs they may have. Visitors will also be able to see how the Fronius welding systems and power sources work first hand during live welding demonstrations.

Documenting, visualising and analysing welding data are becoming increasingly important in many production operations. With the WeldCube data management system, which for the first time is also being showcased as an on-site variant (i.e. purely as a software solution), Fronius is making it possible to record, analyse and evaluate welding data across multiple power sources. This helps the user to identify potential areas for optimisation in welding production lines. In welder training too Fronius is bringing new technologies to the table. The company’s “Virtual Welducation” app takes a fun approach to welding with games, a quiz and an augmented-reality application.

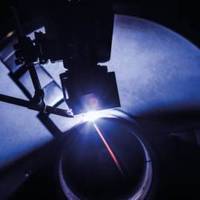

To meet the challenge of increasingly quicker production processes yet with simultaneously high expectations regarding quality in robotic welding, Fronius offers the LaserHybrid welding process, which combines the advantages of the MIG and laser-beam processes. LaserHybrid can now also be used with advantages of the intelligent TPS/i platform. This means users benefit from the new, modular power source technology as well as new characteristics and processes. Fronius has also developed a mechanised application for TIG welding, which aims to achieve a high level of efficiency without compromising on the quality of the weld seam: using ArcTig dramatically reduces the need for preparatory work and rework. What is more, the welding process delivers much higher welding speeds than conventional TIG welding.

Fronius will also be presenting a new product series for manual TIG welding in Düsseldorf. The MagicWave 230i and the TransTig 230i are the first power sources from the manufacturer that can communicate with other devices using Bluetooth, WLAN and NFC technology. After all, manual welding systems are no exception when it comes to demands for ever more connectivity. The TIG solutions – the MagicWave 190 and 230i, and the TransTig 230i – are ideal for applications that require a high weld-seam quality and perfect appearance. Another innovation from the company enables users to flexibly solve a variety of day-to-day challenges: the TransSteel 2200 combines MMA, MIG/MAG and TIG welding in a single device, making it ideal for varied tasks. It is characterised by its user friendliness, robustness and long-term reliability and, weighing in at just 15.5 kg, is one of the lightest power sources for manual welding.

These new solutions will be on show at Schweissen & Schneiden in Düsseldorf (Hall 10, Stand F22/H22) from 25th