Weld Cleaning System offers alternative to toxic methods.

Press Release Summary:

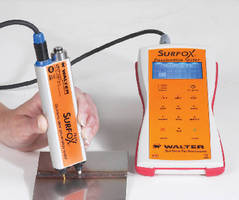

Replacing mechanical abrasion and pickling paste with electrolyte solution, SURFOX produces consistent finish on stainless steel. Unit pumps conductive electrolyte solution through application pad, which simultaneously cleans and passivates part at 3–6 fpm. Internal circuitry provides steady current, so cleaning unit has no down-time. Using illuminated panel to display numeric value of passivation on surface, passivation tester enables workers to evaluate quality of weld cleaning.

Original Press Release:

Walter Surface Technologies' Surfox a Winner for Stainless Steel Welders:

Fastest weld cleaning and passivation system on the market and safest alternative to highly toxic traditional methods

Windsor, CT — WALTER SURFACE TECHNOLOGIES is pleased to announce improvements to the SURFOX weld electro-cleaning system. Underscoring Walter’s commitment to developing greener alternatives for the metalworking industry, this alternative to highly toxic methods for weld cleaning and chemical passivation now offers better cleaning performance, new models, a larger range of accessories, and an improved stainless steel passivation tester. “More and more clients require high quality, clean and visibly pleasing welds. The older methods of cleaning welds are costly, unsafe and complicated. Our experts in the R&D department have truly cracked this case… Surfox is a winner.” says Timothy Houghton, President and COO of Walter Surface Technologies International.Â

Surfox – Farewell to grinding and hazardous pickling pastes

Welding stainless steel often leaves a heat tint on the surface that metal fabricators must remove in order to satisfy the demand for a clean, fully passivated surface. Grinding is time-consuming, labour intensive, and not always effective. Cleaning with pickling pastes exposes the workers and the environment to toxic compounds and can be difficult to use.

Ideal for the food and beverage, pharmaceutical, architectural and transportation industries, Walter’s Surfox system replaces mechanical abrasion and pickling paste with an electrolyte solution. The result is a safer, healthier industrial environment for the worker and a more efficient work process that lowers costs and produces a qualitative, consistent finish on stainless steel. In a typical application, the worker fills the weld cleaning machine with a highly conductive electrolyte cleaning solution. When switched on, the unit pumps the solution through an application pad, which simultaneously cleans and passivates the part – at a rate of three to six feet per minute. After the electro-cleaning process, the worker applies a neutralizing fluid to rebalance the pH of the solution. The result is the best finish in the industry – even a polished finish is possible.

Surfox’s new models and new features

(available in USA only, throughout 2012)

3 new models

- 204Â Â Â Â Â Â the most versatile unit for a wide variety of jobs

- 104Â Â Â Â Â Â the perfect unit for production work

- mini     light and portable machine ideal for onsite jobs, touch-ups and repairs

Walter’s R & D department has introduced several new improvements and features to the Surfox system, including:

• Improved internal circuitry. New inverter boards provide non-stop cleaning, offering higher performance and productivity. The new circuitry provides a steady current, so the cleaning unit has no down-time, and enables the use of highly conductive materials for new accessories.

• More machine settings for electrochemical cleaning. With the flexibility of 3 settings (on the Surfox 204 machine only), the worker can set the unit to Low, Medium, or High according to the required cleaning level.

• A new carbon fiber brush for precision cleaning. The high conductivity of carbon fiber results in greater electrochemical cleaning power, making this new accessory ideal for intricate, narrow areas or tight corners. This accessory is sold separately.

• A large graphite insert and pad. This new accessory is ideal for larger areas and for small surface renewing. Highly conductive, the large long-lasting graphite insert and pad result in greater electrochemical cleaning power.

• Improved passivation tester. This tool enables the worker to evaluate the quality of the weld cleaning and passivation. An illuminated panel displays a numeric value to indicate passivation on the surface. The tester also features data-logging capability and protects data from tampering.

Metal fabricators who use the Surfox system save time and money, improve working conditions, and reduce their environmental impact. In fact, 70% of new customers abandon traditional methods in favor of Surfox. Click here to view a product demonstration video.

Surfox electrolyte solutions are NSF certified for use in the food industry and the Surfox system is ASTM-A967 / ASTM-A380 certified for chemical passivation on stainless steel.

About WALTER – 60 years of success

Walter Surface Technologies has been a leader in surface treatment technologies for 60 years, providing high productivity abrasives, power tools, tooling, chemical tools and environmental solutions for the metal working industry. Founded in Montreal in 1952, the company is now established in 7 countries throughout North America, South America and Europe. US headquarters are located in Windsor, Connecticut. For additional information: www.walter.com