Weight Controller features change-of-rate capability.

Press Release Summary:

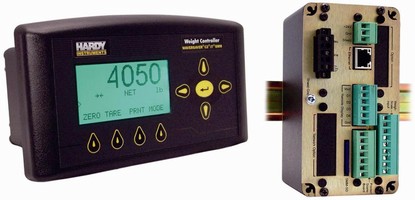

Measuring 3 in deep, HI 4050 incorporates 4 independent analog outputs that can be configured to any instruments parameter. It uses Modbus TCP/IP network communications and offers rate-of-change weight monitoring capability that lets flow rate of material be monitored on scale in gain- or loss-in-weight applications. Modular controller also includes WAVERSAVER® vibration compensation, C2® electronic calibration, Secure Digital-based memory card, and diagnostics/troubleshooting tools.

Original Press Release:

Hardy Instruments' HI 4050 Line of Weight Controllers Now Features Weight By Rate Capabilities, Analog and Modbus TCP/IP Communications

San Diego, CA (short version) - Only three inches deep, Hardy Instruments' HI 4050 general-purpose weight controller is now available with a rate-of-change weight monitoring capability, four-channel Analog, and Modbus TCP/IP network communications. The rate-of-change mode allows you to monitor the flow rate of a material on a scale in either gain-in-weight or loss-in-weight applications. Four independent analog outputs, two current and two voltages can be configured to any of the instruments parameters. Modbus TCP/IP is a vendor-neutral and open communication protocol, suitable for supervision and control of automation equipment. The Modbus/TCP protocol operates on all physical network layers supporting TCP/IP, which compromises 10BASE-T and 100BASE-T LANs.

The HI 4050 weight controller includes WAVERSAVER® to eliminate the effects of surrounding vibration for fast, stable weight display, C2® electronic calibration without test weights, a Secure Digital (SD) based Secure Memory Module card for fast transfer of configuration data, and INTEGRATED TECHNICIAN® for system diagnostics and troubleshooting.

An ISO 9001-certified manufacturer, Hardy Instruments is based in San Diego, California. For more information about Hardy Instruments, please visit www.hardyinstruments.com or call 1-800-821-5831.

San Diego, CA (long version) - Only three inches deep, the HI 4050 general-purpose weight controller is the first of a new line of modular controllers by Hardy Instruments. It is used in tank farm, batching/blending, filling/dispensing, check weighing, level by weight, and force measurement applications. The weight controller is now available with a rate-of-change weight monitoring capability, four-channel Analog, and Modbus TCP/IP network communications. The rate-of-change mode of weighing allows you to monitor the flow rate of a material on a scale in either gain-in-weight or loss-in-weight applications. This rate data can be displayed locally or remotely over any available networks.

Four independent analog outputs, two current (4 - 20 ma, etc) and two voltage (0 - 10 v) can be configured to any of the instruments parameters over an adjustable 16,000 counts of resolution.

Modbus TCP/IP is a vendor-neutral and open communication protocol, suitable for supervision and control of automation equipment. The Modbus/TCP protocol operates on all physical network layers supporting TCP/IP, which compromises 10BASE-T and 100BASE-T LANs.

To meet your specific installation needs, the HI 4050 is available with AC or DC power and in panel, remote or blind DIN rail mounting packaging configurations. Installations are simplified with no special tools required to cut rectangular holes. Just use the included template to drill standard holes and install. The controller includes a standard Ethernet 10/100 Base T with an embedded web server and an RS 232 printer or scoreboard display port. Optional network communications over Ethernet/IP or DeviceNet are also available.

The HI 4050 weight controller includes Hardy Instruments' core technologies:

o WAVERSAVER®, which eliminates the effects of surrounding vibration to provide a fast, stable weight display

o C2®, which allows for electronic calibration without the need for test weights

o Secure Memory Module with Secure Digital (SD) card (SMM®-SD), which allows manual transfer of configuration data to another instrument or PC using SD technology

o INTEGRATED TECHNICIAN® (IT) for system diagnostics and troubleshooting

Hardy Instruments has been a leader in weighing solutions for over 80 years and is best known for its innovative approaches to precision weighing and vibration monitoring equipment. An ISO 9001-certified manufacturer, Hardy Instruments is based in San Diego, California. For more information about Hardy Instruments, please visit www.hardyinstruments.com or call 1-800-821-5831.