Waterjet Cutters and Cutting Machinery

Waterjet Machining Center offers Rotary Axis accessory.

Press Release Summary:

When equipped with Rotary Axis, JetMachining® Center cuts X/Y/Z paths to create complex 3D parts with incremental index rotations from pre-existing CAD/DXF files. Rotary Axis is suited for cutting pipe, circular, or square stock materials and designed with multiple mounting features on output drive shaft. Users can position head in various locations in tank and attach customized fixtures. Fully submergible, rotary head contains built-in water drip sensor.

Original Press Release:

OMAX® Rotary Axis Accessory Facilitates Complex Design Capabilities

Kent, Washington, December 9, 2008 - OMAX® Corporation's Rotary Axis is the latest offering in the company's line of industry-leading precision abrasivejet machining products. When equipped with a Rotary Axis, the OMAX JetMachining® Center cuts XYZ paths to create complex 3D parts with incremental index rotations from pre-existing CAD drawings or .DXF files. The accessory is available for installation on all OMAX JetMachining Centers and opens more design capabilities.

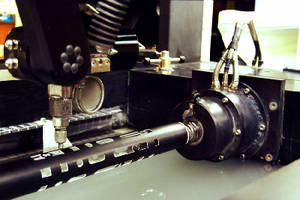

The Rotary Axis is ideal for cutting pipe, circular or square stock materials and is designed with multiple mounting features on the output drive shaft. The accessory's drive head also allows users to attach customized fixtures. The versatile attachment design allows users to position the head in various locations in the tank. The horizontal Rotary Axis provides cutting adaptability in the Z travel direction and adds several height options for the part's design.

Fully submergible and powered by common table controls, the rotary head does not require an additional power supply. The accessory also contains a built-in water drip sensor with warning lights and automatic shutdown. Additionally, the Rotary Axis is equipped with external grease fittings for easy maintenance.

The vertical waterjet allows for a safer, cleaner and quieter process. Waterjet technology also eliminates heat-affected zones when cutting metal materials. An OMAX JetMachining Center can reduce the cutting time to produce parts when compared to lengthy CNC milling processes.

OMAX believes in manufacturing the best machines and accessories possible with the best software available, and works to continually develop cutting-edge technology and innovative software for its customers. As a result, each OMAX product comes with the OMAX Technology Guarantee, which provides software upgrades for all existing customers at no additional charge.

About OMAX

Headquartered in Kent, Washington, OMAX ® Corporation is the leading manufacturer of precision abrasive waterjet systems. Each OMAX JetMachining® system is powered by the company's innovative control software, bringing affordable abrasivejet technology to an expanding and diverse group of industries. For more information on OMAX products and accessories, contact Sandra McLain at 800.838.0343 or visit www.omax.com.