Waste Heat Recovery System offers flue gas scrubbing.

Press Release Summary:

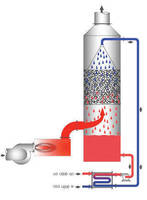

Utilizing counter current flow exchanger, QSense™ recovers waste heat BTUs from boilers, kilns, dryers, ovens, thermal oxidizers, and incinerators. Sensible and latent heat recovery promotes efficiency, and flue gas scrubbing removes particulate and gaseous contaminants. Offered in vertical configuration, this direct contact waste heat recovery system comes with all necessary components. Neutralizing chemical reagents, pre-scrubber, and clog-resistant contactor are available options.

Original Press Release:

New Qsense(TM) Direct Contact Waste Heat Recovery System Economically Recover BTU's from Hot Gases

Bionomic Industries Inc., a world-wide leader of proven air pollution abatement, product, and heat recovery technologies, has announced availability of their QSense Direct Contact Waste Heat Recovery System.

Designed to economically recover valuable waste heat BTUs from boilers, kilns, dryers, ovens, thermal oxidizers and incinerators, QSense’s highly efficient counter current flow exchanger typically provides a full savings payback within 1 to 3 years for most applications. The recovered heat can then be used to preheat boiler feed water, meet or supplement building space heating requirements, or for heating process heat transfer fluids.

Both sensible and latent heat is recovered for maximum recovery efficiency and, as an added benefit, flue gases are scrubbed to remove any particulate and gaseous contaminants that are present to reduce plant emissions.

The QSense Heat Exchanger is offered in a vertical configuration for maximum space savings, and with all necessary system components. For flue gases containing acid contaminants the unit can be equipped with neutralizing chemical reagents and for particulate laden streams, a pre-scrubber and clog-resistant contactor is available.

For more information, call 201-529-1094, e-mail sales@bionomicind.com or visit www.bionomicind.com .