Waterjet Cutters and Cutting Machinery

WARDJet Introduces Ability to Use WATERJET as a Digitizer

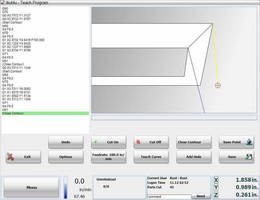

WARDJet - Tallmadge, Ohio: If customers come to you with physical parts but they have no drawing or electronic file, you can use the digitizing capability of a WARDJet waterjet to reverse engineer these types of parts. Also, if these parts are large, it may be easier to lay the part on the waterjet table and use the waterjet to memorize the part profile than using a tape measure. With our X-Series controller you can use the waterjet cutting head, or a laser alignment guide mounted near the cutting head, to record the X, Y and even the Z coordinates of a part. Simply click "Teach new part" on the controller screen to start mapping the part geometry. Both lines and arcs can be easily taught. If further clean up is needed, the CNC file can be brought into a CAD/CAM program. Within minutes, you can go from part to electronic file.

About WARDJet

WARDJet is a leading designer and manufacturer of new and custom waterjet systems for precision cutting and machining applications. Their open-architecture CNC platforms are designed to accommodate multiple machining processes such as drilling, tapping, reaming, rotational indexing or multiple-head 5 axis waterjet cutting. WARDJet waterjet systems are made in the U.S.A. For more information contact the Sales Department, ph: 330-677-9100, ext. 6; fax: 330-677-9121; www.wardjet.com, sales@wardjet.com.