Vision Software inspects packages, containers and labels.

Press Release Summary:

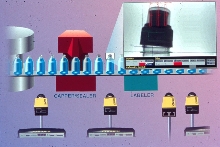

Capinspect inspects container caps for presence/absence, skew, height, and container fill level while Labelinspect checks package labels for presence/absence, measures label position, and inspects logos, decorations and other features. Show-and-Go graphical user interface on both enables users to train package features by simply drawing box around area to be inspected and clicking button on toolbar. Both work with company's vision systems.

Original Press Release:

Cognex Introduces Package Inspection Software Applications For In-Sight Vision Sensors

Atlanta, GA and Natick, MA, November 14, 2001-Cognex Corporation (NASDAQ - CGNX), the world's leading supplier of machine vision systems, today introduced two high-performance package inspection software applications for use with the company's award-winning In-Sight vision sensors. Designed to solve a variety of common package inspection tasks in the food, beverage and pharmaceutical industries, the new applications feature a pre-configured Show- and-Go graphical user interface that dramatically simplifies and accelerates the process of implementing vision onto packaging lines. Applications include:

* Capinspect- inspects container caps for presence/absence, skew, height, and container fill level.

* LabelInspect- inspects package labels for presence/absence, measures label position, and inspects logos, decorations, and other features on labels.

"In today's packaging industry, manufacturers are looking for 'out-of-the-box' inspection solutions that can be easily implemented and can accommodate fast product changeovers," said Justin Testa, Senior Vice President of Marketing for Cognex. "Leveraging our years of experience in the packaging industry, we have developed simple, powerful solutions that make it easier than ever for companies to add vision to multiple points on the packaging line where automated inspection is needed."

The Show-and-Go graphical user interface, common to each application, enables users to train package features by simply drawing a box around the area to be inspected and clicking a button on the toolbar. Menu-driven wizards guide users step-by-step through the process of selling up all aspects of the application, from inspection parameters to communications with other automation equipment. In production mode, users can view a live image display of the inspections as they occur, as well as a running tally of pass/fail results and statistical process information. Users also have access to the complete library of general-purpose In-Sight vision tools for applications that may require additional functionality.

The new applications are currently available from Cognex, and can be purchased for use with In- Sight 1000, 2000, and 3000 vision sensors. In-Sight vision sensors are low-cost, high- performance, on-line inspection devices that are used to automatically measure parts, verify the correct assembly of products, identify parts, and guide production equipment. In-Sight sensors have become the standard for low-cost machine vision in the packaging industry, and are helping pharmaceutical manufacturers gain compliance with the U.S. Food & Drug Administration's 21CFR Part 11 regulations.

Cognex Corporation designs, develops, manufactures, and markets machine vision systems, or computers that can "see." Cognex is the world's leader in the machine vision industry, having shipped to date more than 150,000 machine vision systems, representing over $1 billion in cumulative revenue, since the company's founding in 1981. Cognex's Modular Vision Systems Division, headquartered in Natick, Massachusetts, specializes in machine vision systems which are used for automating the manufacture of a wide range of discrete items and for assuring their quality. Cognex's Surface Inspection Systems Division, headquartered in Alameda, California, specializes in machine vision systems which are used for inspecting the surfaces of products that are manufactured in a continuous fashion, such as metals, paper, and plastics. In addition to its corporate headquarters in Natick, Massachusetts, Cognex also has regional offices located throughout North America, Japan, Europe, and Southeast Asia..