Vertical Tapping Centers have 394 ipm milling speed.

Press Release Summary:

With cast mono-block bed design, VTC 30A and 30B feature traverse rates of 1,653 ipm (X and Y axes) and 1,772 ipm (Z axis) across X-, Y- and Z-axis travels of 17.32, 11.42, and 10.62, respectively. Contained within 44.8 x 84.64 in. footprint, products utilize GE Fanuc 21i Mb control as well as servomotors directly coupled to ball screws. Automatic tool turret, with 10-tool capacity, is available on VTC 30A with 1.3 sec station-to-station index time.

Original Press Release:

New ROMI VTCs Offer Precision, Speed & Repeatability in Tapping

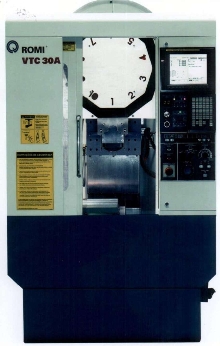

ERLANGER, KY - Romi Machine Tools, Ltd, long an industry leader in turning and horizontal and vertical machining center technology, introduces the VTC 30A/30B vertical tapping centers (VTCs). The VTCs are a highly flexible, efficient and accurate solution for mixed volume, short-run operations as well as dedicated high-volume applications. Tool room and production facilities alike, as well as the many current Romi turning and milling machine users, are ideal candidates for the new VTC 30A/30B.

The VTCs combine high performance and rigid tapping capacity within a compact 44.8" x 84.64" space-saving footprint. Rapid traverse rates of 1,653 imp (X-and Y-axis) and 1,772 imp (Z-axis) mean accelerated machine cycle times and reduced non-cut time which increases overall throughput. Programmable milling speed is 394 ipm.

Servomotors directly coupled to high-precision ball screws provide excellent acceleration and deceleration performance as well as precise feed movement. Also minimizing cycle time is an automatic tool turet with 10-tool capacity on the VTC 30A and a fast 1.3 second station-to-station index time. The 20-tool double arm VTC

The VTC 30A/30B cast mono-block bed design supports the vertical headstock and table, providing outstanding vibration dampening and the rigidity and stability required for today's heavy tapping needs. The headstock and table travel on automatically lubricated ball screw-driven linear guides that guarantee ultra-precise positioning, accuracy and repeatability.

The spindle. The headstock with main spindle is supported by ultra precision bearings designed to operate at high speeds. A new pulley and poly-V belt heavy-duty headstock features a high-torque 7.5 hp GE AC high-precision spindle motor with greater power transmission efficiency and low noise level. The ISO 30 spindle achieves speeds ranging from 8 to 8,000 RPM (optional 12 to 1,2000 RPM). The headstock has been specifically designed to provide superior rigidity to ensure precision tapping, even during full-power machining in steel. Maximum rotation for rigid tapping is 394 ipm. Drilling capacity: aluminum A1-A4 13.1, 1/02"; GG 20, 0.94"; SAE 1045, 0.86". Threading: aluminum A1-A41 3.1, 0.79"/M20; GG 20, 0.63"/M16 and SAE 1045, 0.55"/M14.

The table. The table work surface is an ample 19.68" x 12.59". X-axis travel is 17.32", Y-axis travel is 11.42" and Z-axis is 10.62". Accuracy of positioning (X-, Y- Z-axis) is 0.00019", and repeatability (X-, Y-, Z-axis) is 0.00012".

An fully automated lubrication system and coolant system, and complete machine enclosure with front and side doors for easy access to the work area are standard.

The control. The GE Fanuc 21i MB features the latest technological advancements in a uniquely small space. The 10.4" color LCD and full keyboard conveniently swivel for ease of operation. A shock absorber keeps the control in position when keys are pressed.

As the Romi VTC 30A/30B is generally used as a production machine, 21i MB can be programmed offline or online using G code language and standard G code features available from GE Fanuc.

For more than 70 years and some 140,000 installations Romi's innovation, reliability, dependability and ease-of-use have set it apart - and ahead of - the competition. Romi's combination and CNC lathes, turning centers and horizontal and vertical machining centers are meticulously built at its eight-plant manufacturing complex in Santa Barbara d'Oeste, Brazil, and are sold and supported in more than 60 countries. From its North American Headquarters in Erlanger, Kentucky. Romi provides an unparalleled degree of training, service and support for all Romi machine tool products.

For more information, contact Romi Machine Tools, Ltd; 1845 Airport Exchange Blvd.; Erlanger, KY 41018. Tel: 859/647-7566. Fax: 859/647-9122. Toll Free US & Canada: 1-877-ROMIUSA. www.romiusa.com. e-mail: sales@romiusa.