Ultrasonic Perforating of Foam-Based Wound Dressings

Dressings made from a soft foam-based laminate with an adhesive and perforated contact layer are air-permeable and absorb blood and wound secretions. The product also protects bedsores from being further strained by pressure.

Ultrasonic perforating without heat improves product performance

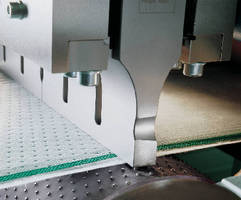

The contact layer must adhere reliably to the skin, absorb wound secretions and yet be gently removable from the skin. To ensure this they are perforated ultrasonically. The principle of ultrasonic welding for thermoplastic material forms the basis whereby line voltage is first converted into an ultrasonic frequency and secondly into mechanical vibrations by using the reverse piezoelectric effect. A cold tool, called a sonotrode, introduces the ultrasonic vibrations into the material and causes a very controlled molecular friction. The pin shaped contact areas on an embossed anvil drum define the perforation pattern - the drum functions as a rotating anvil and is decoupled acoustically to ensure optimum results.

In a production environment, the web material passes between the anvil drum with a raised pin pattern and multiple sonotrodes lined up across the width of the web. The pin holes are generated without a noteworthy amount of heat. Unlike heat perforation, the amount of energy and heat required during ultrasonic perforation is very low. This positively impacts the product performance in terms of the layer's adhesive properties. The higher heat levels associated with heat perforation may influence the laminate material negatively.

Faster production speeds with ultrasonic technology

Also, Ultrasonic perforation technology allows a two to three times faster production speed compared to heat perforation systems. Additionally the product quality remains constant even at varying speeds during the start-up and deceleration phases of the machine. Another benefit of ultrasonics is immediate system readiness of the machine as it doesn't have to heat up. If different materials are being processed, process parameters can be changed immediately and setting different memories is very simple. The Microgap Control developed and patented by Herrmann Ultrasonics accurately controls the distance between the anvil drum and sonotrode to the micrometer and guarantees process monitoring and repeat accuracy. Overall Equipment Efficiency (OEE) increases.

Functional principle: ultrasonic perforating of nonwovens