Transport System is designed to facilitate start-up.

Press Release Summary:

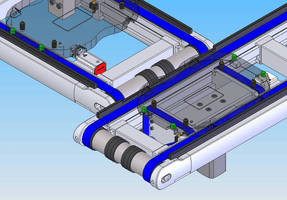

Wired and tested prior to delivery, transport system consists of double belt that carries individual workpiece holders. They are equipped with RFID and can be identified at any time, enabling chaotic operation. Motor is integrated in drive roller, and there are no protruding parts. System comes complete with software, which runs without superior control.

Original Press Release:

Montech: New Transport System Saves Time During Start-Up

(Derendingen) At Motek 2012 in Stuttgart (Hall 1, Stand 1180), the Swiss specialist of transport systems is introducing a new developed transport system, that is wired and tested before delivery.

The new transport system consists of a double belt, which carries individual workpiece holders. They are equipped with RFID and can be identified at any time, thus enabling “chaotic” operation. The motor is integrated in the drive roller, with no protruding parts. The application of energy-saving technology results into high efficiency levels of the transport system.

Simple, time-saving start-up

The new transport system is delivered by Montech complete with software, which runs without superior control, and wiring. The transport systems is checked and tested before shipping, so that the user has minimal costs in times and saves time during start-up.

The transport system is provided with several components for different requirements, offering a wide and diversified application spectrum. “Consistently with Motek’s motto ‘Invent the future’, we have developed a new, innovative transport system with trend-setting characteristics,” says Gianluca Aloisi, Director Sales at Montech.

Customer-specific solutions with Vacuum conveyor

Visitors at Montech’s stand in Hall 1, Stand 1180, will have the opportunity to see customized solutions based on conveyors. Among these, Montech is presenting an application featuring a longitudinal transfer system combined with a vacuum conveyor to carry and sort CDs: the vacuum conveyor sorts out CDs according to predefined categories, then a closed loop transfer system carries away the CD stack.

“It’s an endless working cycle, including picking, transport and placing operations, without unproductive return strokes, designed to optimize the sorting process,” explains Aloisi. The vacuum conveyor runs at a speed of five meters per second, which helps to increase process productivity.

Flipping module for soft overturning

At Motek, Montech will also show the so-called flipping module, which can turn glass sheets or displays upside down, rotating them around their cross axis. The special belts of foamed materials are soft; they grip and turn the workpiece upside down very softly. The flipping module can also carry workpieces without turning them upside down.

Montech AG

Montech AG markets basic modular components for the automation of demanding transport, assembly and production processes. In addition to conventional conveyor belts, the product range includes automation components and the Quick-Set profile system. A specialist in standard and customized transport and conveyor systems, Montech offers an ideal combination of customer-specific solutions with a high degree of standardization. Founded in 1963, the company is based in Switzerland and stands for innovation in the automation industry.

For more information

Montech AG

Elke Manthei

Gewerbestrasse 12

CH-4552 Derendingen

Phone: +41 (0)32 6815542

Fax: +41 (0)32 6821977

E-Mail: elke.manthei@montech.com

www.montech.com