Total 3D - Viscom Presents AOI Module with 3D Technology

Hanover – Productronica 2013, Hall/Stand A2-177

Established in 1984, Viscom has been developing innovative solutions for optical and X-ray inspection for almost 30 years. Working closely with customers, Viscom bases its inspection systems on the latest trends and requirements in SMT production. From the start, the inspection technology was designed to inspect 3D characteristics such as 3D solder paste inspection or the 3D functions of off-line and in-line X-ray inspection, up to the complete uCT. At Productronica 2013, Viscom will present the latest building block in the expansion of the 3D performance spectrum: the 3D function in the AOI high-performance camera module XM.

Increased miniaturization of pads and the resulting greater need for vertical and horizontal resolution were crucial for expansion of 3D technology into end-of-line inspection. The use of angled views already allowed for observation from various viewing directions in order to reliably detect critical errors in the fine-pitch range.

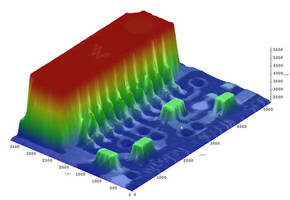

To meet the latest as well as future requirements in electronics manufacturing, not only must the inspection object as a whole be reliably detected, but each individual point of the object as well. This problem is now solved in the XM module with the help of a structured light projector and a multi-step laser triangulation procedure. Here, Viscom relies on the unique, optimal principle of a structured light projector, whose projection is picked up by four or eight side-looking cameras.

In conjunction with the powerful XM module, this configuration produces an optimal combination of all individual measurement principles in the AOI area, creating a comprehensive optical inspection system. With an image acquisition rate up to 1.8 gigapixels/second, the new XM module is extremely fast and because of additional high resolution, it is able to incorporate all information with maximum speed into a highly precise 3D inspection. The unique, flexible camera projector configuration, which uses the existing angular AOI cameras, allows for, uncomplicated 3-D retrofit by only installing the structured light projector since the cameras are already present in the AOI system.

About Viscom

Viscom AG manufactures and sells high-quality automatic optical and X-ray inspection systems. The company is one of the leading suppliers of 3-D solder paste inspection, component placement and solder joint inspection equipment in the PCB assembly market. Viscom systems ensure quality in surface mount technology production lines, where they can be interlinked to further improve productivity. The company’s headquarters and manufacturing operation is located in Hanover, Germany. With a wide network of branches, applications and service centers, Viscom is represented throughout Europe, Asia and the Americas. Founded in 1984, Viscom has been listed on the Frankfurt Stock Exchange (ISIN: DE0007846867) since 2006. For more information, visit www.viscom.com.