Tool Changers support standardization.

Press Release Summary:

Sigma 3 and Sigma 5 feature modularity, data capabilities, and electric actuation. They allow interchangeability of interface modules, which are comprised of electrical connectors and utility packages used in manufacturing environments. Units handle variety of bus system requests, allowing user to route, connect, and disconnect electronic pathways to sensors monitoring manufacturing process. They are suitable for material handling and welding robots.

Sigma 3 and Sigma 5 feature modularity, data capabilities, and electric actuation. They allow interchangeability of interface modules, which are comprised of electrical connectors and utility packages used in manufacturing environments. Units handle variety of bus system requests, allowing user to route, connect, and disconnect electronic pathways to sensors monitoring manufacturing process. They are suitable for material handling and welding robots.Original Press Release:

New Generation of Tool Changer Supports Trend Towards Standardization; Modularity, Data Capabilities and Electric Actuation are Key Features

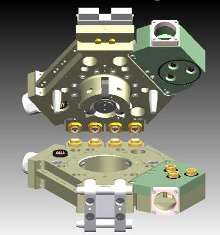

GLENVILLE, NY October 29, 2002 -- Applied Robotics, Inc. (ARI) has introduced the Sigma family of tool changers for heavy-duty material handling and welding robots. They are the first heavy-duty modular tool changers to support the global manufacturing trend towards standard specifications for worldwide factory production equipment.

The Sigma 3 and Sigma 5 tool changers were developed in response to manufacturers' needs to meet ever-faster time-to-market requirements, increased robot flexibility, lower costs and standardized specifications for those who support multiple locations.

The key feature of the Sigma tool changers is the interchangeability of interface modules comprised of all the standard electrical connectors and utility packages typically used in manufacturing environments throughout the world. These commonly stocked components can be used on either the Sigma 3 or the Sigma 5 allowing for easy interchangeability, thus decreasing the need to stock separate component parts for each model.

An additional advantage of the Sigma tool changers is the ability to easily handle the wide variety of bus system requests with its increased modularity. "A decade ago it was typical for a technician to manually inspect part quality or end-of-arm tooling for wear, but today's forward-thinking manufacturers want that data available automatically," said Tom Petronis, CEO, Applied Robotics, Inc. The Sigma series tool changers are the first that let users easily route, connect and disconnect the electronic pathways to sensors monitoring the manufacturing process. The Sigma units allow for electric (servomotor) actuation of end-of-arm tooling, which provides the precise control needed for a robot to work with nontraditional materials when spot welding, clinching or riveting.

About Applied Robotics, Inc.

Applied Robotics, Inc., formed in 1984 and headquartered in Glenville, NY, has a reputation for quality and reliability in the design and manufacture of automation accessories, including; Collision Sensors, Tool Change Systems, Force Sensors, Compliancy Devices, and QuickConnect Systems. Applied Robotics, Inc. is an ISO-9001 registered employee owned company. As an international company serving the world's automation market, their products and services are widely used throughout the manufacturing, welding, medical, food processing, assembly, material removal and material handling markets. For more information, please contact Applied Robotics at (518) 384-1000, fax: (518) 384-1200, e-mail: info@arobotics.com or visit www.arobotics.com.