Timing Belt Backings offer flat or round carrying surface.

Press Release Summary:

Made of polyurethane, TR1 and TR2 Backing Materials feature thicknesses of 2.4 and 2.5 mm with groove depth of 0.5 and 1.4 mm, respectively. Both offer resistance to oil and fats, gasoline, and ozone. With 85 Shore A hardness and temperature range of -4 to 176°F, backing materials are suited for general conveying and wet applications.

Original Press Release:

New Backings "TR1 and TR2"

BRECOflex CO., L.L.C., the pioneer and world leader in the polyurethane timing belt industry is proud to introduce the new backing materials "TR1 and TR2".

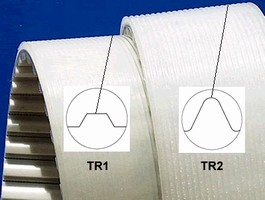

"TR1 and TR2" is representing new polyurethane backings with different longitudinal groove profiles.

The characteristics and properties are as follows:

Material: Polyurethane

Color: transparent

Available thicknesses: TR1 2.4 mm

TR2 2.5 mm

Depth of the groove: TR1 0.5 mm

TR2 1.4 mm

Carrying surface: TR1 flat

TR2 round

Hardness: 85 Shore A

Tolerance: +/- 0.25 mm

Temperature resistance: -4ºF up to 176ºF

-20ºC up to 80ºC

Properties: simple oil and fats resistance, gasoline and ozone

Applications; Conveying in general, ideal for wet applications (water, oil)

Belt backings are available in a wide variety of cover materials which are bonded to the back of timing belts. Superior know-how and state-of-the-art processes assure a strong high performing bond to the polyurethane belt materials. The selection of the most appropriate and best performing backing material always depends on the specific application and functional requirements.

Ask for free "TR1 and TR2" samples and please take advantage of our free engineering support!

Toll free at 1 (888) 463-1400

Tel: 732-460-9500

Email: info@brecoflex.com

Visit our website: www.brecoflex.com