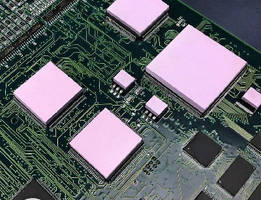

Thermal Interface Material suits high power density systems.

Share:

Press Release Summary:

Consisting of soft and compliant gap filling material, GAP PAD HC 5.0 has thermal conductivity of 5.0 W/m-K and is designed to manage heat generated by high power density components. Product allows for optimized interfacing and wet out, even to rough surfaces and topographies. Available in thickness from 0.508–3.175 mm, GAP PAD HC 5.0 is manufactured with natural tack on both sides, contains no thermally impeding adhesive layers, and is reinforced with fiberglass for shear and tear prevention.

Original Press Release:

Henkel's High Compliance GAP PAD HC 5.0 Provides Excellent Thermal Management Performance for Applications with Increased Power Densities

Henkel Adhesive Technologies’ Electronics business has developed and launched the latest product in its line of award-winning GAP PAD thermal interface materials (TIMs). The new GAP PAD HC 5.0 is designed to manage the heat generated by today’s reduced form factor, high power density components.Â

A soft and compliant gap filling material, GAP PAD HC 5.0 has a thermal conductivity of 5.0 W/m-K and delivers outstanding thermal performance with very low compression stress. The low modulus and unique filler package is ideal for applications that require minimal component or board stress during assembly, yet demand high heat transfer across the interface with very low thermal resistance.

“As electronic components have reduced in size, the power densities have increased,” explains Danny Leong, GAP PAD HC Product Line Manager. “The requirement for effective thermal management is greater than ever before. In the case of high value, high power products like those used within internet and computing infrastructures, superior heat transfer is a necessity and GAP PAD HC 5.0 delivers.” Â

GAP PAD HC 5.0 is the next generation of high compliance, very soft gap filling materials that allow for superb interfacing and wet out, even to rough surfaces and topographies, which ensures uniform material coverage across the component and heat sink for maximum performance. With high compliance materials, low thixotropic stress during assembly and through power and thermal cycling is important for minimizing pressure and potential damage to solder interconnects. Compared to previous-generation materials, GAP PAD HC 5.0 offers better handling, an enhanced dielectric constant, improved volume resistivity and better thermal impedance performance. Manufactured with a natural tack on both sides, GAP PAD HC 5.0 contains no thermally-impeding adhesive layers and is available in a range of thickness from 0.508 mm up to 3.175 mm. Reinforced with fiberglass for shear and tear prevention, the new GAP PAD TIM is also highly durable.

“This new high compliance formulation translates into lower junction temperatures and improvements in device performance,” says Leong in summary. “GAP PAD HC 5.0 is the new generation of high-efficiency thermal interface materials for advanced, high power density electronics.”

For more information about GAP PAD HC 5.0, visit www.henkel-adhesives.com/thermal or call +1-952-835-2322.Â

Henkel in North America

Henkel markets a wide range of well-known consumer and industrial brands in North America, including Dial® soaps, Purex® laundry detergents, Right Guard® antiperspirants, got2b® hair gels, and Loctite® adhesives. Visit www.henkel-northamerica.com for more information.

About Henkel

Henkel operates worldwide with leading brands and technologies in three business areas: Laundry & Home Care, Beauty Care and Adhesive Technologies. Founded in 1876, Henkel holds globally leading market positions both in the consumer and industrial businesses with well-known brands such as Persil, Schwarzkopf and Loctite. Henkel employs almost 50,000 people and reported sales of $20.1 billion and adjusted operating profit of $3.2 billion in fiscal 2015. Henkel’s preferred shares are listed in the German stock index DAX.

Contact

Henkel Adhesive Electronics Â

Doug Dixon   Â

Phone:Â +1-714-368-8000

Fax:Â Â Â Â Â +1-714-368-2265

doug.dixon@henkel.com

www.henkel-adhesives.com/electronics