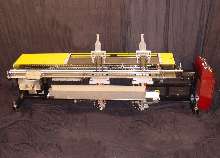

Takeaway Detabber System suits blow molding industry.

Press Release Summary:

Model 2001E works with shuttle type blow molder machines including Bekum 120, 121, 151, 155 and Fischer 054 and 106. Detabber and grippers virtually eliminate jams. Machine operates on 120 Vac single phase power and requires ½ in. compressed air line with 90-100 psi. Container sizes range from 5-12 in. in height and 1.25-6.85 in. in depth. Production rate is based on production rate of blow molder.

Original Press Release:

MTM Systems Unveils Advanced Takeaway Equipment

MTM Systems, a division of Lectro Engineering has begun shipping the most versatile takeaway detabber systems in the industry. "The new 2001E is exactly what any company that blow molds containers is looking for" states Lee Hyde COO and Director of Marketing. "No other manufacturer has a takeaway that cost so little and can work with so many shuttle type blow molder machines. These include the Bekum 120, 121,151,155 and the Fischer 054 and 106. We have also redesigned the detabber and grippers to virtually eliminate jams."

It took MTM Systems two years and input from many customers in building the ultimate takeaway and detabber system. Another benefit is the 40% reduction in moving parts from the original 2001E.

MTM System estimates a threefold increase in takeaway business based on preproduction orders, the recent changes in the tax law regarding write offs, and the reduced initial capital investment of the equipment.

The 2001E operates on 120 VAC single phase power and needs a ½ inch compressed air line with 90-100 PSI. The production rate is based on the production rate of the blow molder. Container sizes range from 5" to 12" in height and 1.25" to 6.85" in depth.

For more information you can contact us at: Lectro Engineering 1643 Lotsie, St. Louis, MO 63132. By phone at 314-567-3100 or fax at 314-567-3466 or visit our website at www.lectrotreat.com.