Stress Relief System offers manual and automatic operation.

Press Release Summary:

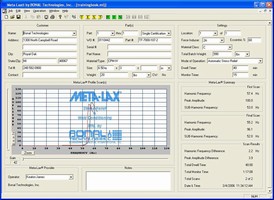

Meta-Lax Model 2700-CC sub-harmonic stress relief system uses Windows OS and incorporates software that adds 2 manual modes to 2 existing automatic modes. While giving operator control over entire process, manual modes also expand capacity to use vibrations to address applications other than stress relief and weld conditioning. Data entry on certification sheet includes metric conversions to clarify information about workpiece and stress relief certification.

Original Press Release:

Bonal Technologies, Inc. Introduces Software Upgrade for Meta-Lax 2700 at IMTS

ROYAL OAK, Mich., August 30, 2006 - Bonal Technologies, Inc., a subsidiary of Bonal International, Inc. (OTC: BONL), is introducing a software upgrade for its Meta-Lax sub-harmonic stress relief system Model 2700-CC at the IMTS 2006 Exposition and Conference at the McCormick Center in Chicago. Bonal will demonstrate the technology in Booth #B-6448.

The upgraded Model 2700-CC software features two manual modes that were not available with the previous version. In the past the software featured the two automatic modes - one for Meta-Lax stress relief and the other for Meta-Lax weld conditioning. The manual modes of operation will add four advantages. First, the manual mode will generate more details of the complete Meta-Lax operation on each certification sheet. Second, the manual modes will give the operator more control over the whole process instead of being computer controlled. Third, it will be easy to introduce Meta-Lax technology to new customers using the manual modes. Fourth, the manual modes will expand the capacity to use vibrations to address non stress relief and weld conditioning applications.

"I believe most customers will still prefer the automatic modes of operation, but the manual modes will offer some nice new options to our customers," said Tom Hebel, Vice President of Bonal Technologies, Inc.

Bonal Technologies also made some refinements to the automatic modes and certification sheets. For example, the new data entry on the certification sheet will include metric conversions. This data is used to clarify the information about the workpiece and the stress relief certification.

The software upgrade represents the third generation. In the last generation, Bonal changed the software from DOS to Windows operating system.

Bonal tested the software upgrade with several current Model 2700-CC customers who responded very positively about the changes.

Current Bonal customers that own the Model 2700-CC system can purchase the upgrade on CD-ROM for $695. The software is expected to be available mid- to late-April and will be able to be easily installed just like any other software without modification to the electronics of the control console. All previous job information will still be accessible using the new software.

Bonal Technologies, Inc., a subsidiary of Bonal International, Inc. (otc, BONL) is the world's leading provider of sub-harmonic stress relief technology for metal improvement solutions with more than 35 years of expertise. Headquartered in Royal Oak, Mich., Bonal Technologies, Inc. provides solutions to prevent distortion and cracking for metal components. Bonal's patented technology and its three product lines: Meta-Lax® Stress Relief, Pulse Puddle Arc Welding® (PPAW®) and Black Magic® are sold in the US and in 49 countries. The company serves customers in a wide range of industries - aerospace, automotive, construction equipment, defense/ homeland security, die casting, engine building/racing, foundries, machine tool/mold making, mining, petroleum, power, plastic molding, shipbuilding, structural steel construction, steel producers and welding/fabricating industries.