Strand Pelletizer offers extra large cutting width of 200 mm.

Share:

Press Release Summary:

Featuring single-side mounted design, PRIMO 200E is suitable for compounding of thermoplastics, masterbatch production, and production of color concentrates up to line-throughput rate of 1.5 tons/hr. System includes cutting tool sets for hard, abrasive and soft, flexible plastics. Pellet dimensions can be changed using optional automatic pellet length adjuster. Since feed geometry is designed without major deflections, plastic strands are not subjected to pre-tensioning prior to cutting.

Original Press Release:

Automatik Plastics Machinery Displays New PRIMO 200E at the K Show in Dusseldorf (Stand 9A04 Hall 09)

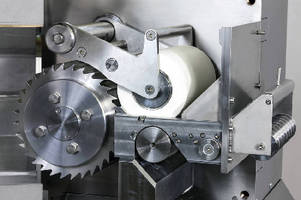

PRIMO 200E is a new single-side mounted dry-cut strand pelletizer with an extra-large cutting width of 200mm. PRIMO 200 E combines a broad range of skillfully designed product features delivering user friendliness and productivity.

Among single-side mounted strand pelletizers the PRIMO 200E scores highly thanks to its unique cutting geometry with the shortest unguided length between the feed rolls and the cut. This geometry enables optimum straight cutting of both hard and very soft plastic strands, all in top quality.

The PRIMO 200E is particularly suitable for compounding of thermoplastics, for functional and additive masterbatch production and for the production of color concentrates up to a line throughput rate of 1.5 tonnes per hour.

Highlights of the PRIMO 200E are its cutting tool sets for hard, abrasive and soft, flexible plastics. The pellet dimensions can be quickly changed by means of an optional automatic pellet length adjuster. This is done using a second drive motor for the feed mechanism with an integrated speed control.

When processing abrasive products and at high production temperatures, the Primo 200E can optionally also be equipped with a separately driven, highly wear-resistant metal feed roll instead of the standard elastomer feed roll.

The design of the PRIMO 200E makes it an outstanding choice for the efficient production of micro-quantities of color masterbatches and concentrates. It is easy to clean, features a low-deposit cutting chamber and enables short retooling times, and the cutting and tool changing process is likewise quick and easy.

Automatik Plastics Machinery places the greatest value on maximum reliability, and that commitment is reflected in the strong and rugged design of this cantilevered pelletizer.

Another special feature of the new machine is that the feed geometry is designed without major deflections, so the plastic strands are not subjected to pre-tensioning prior to cutting. This means that even highly fragile polymers such as polystyrene or highly filled masterbatches can be pelletized in high qualities, nearly without longs or dust.

Press contact:

Automatik Plastics Machinery GmbH

Ruth Ploch

Ostring 19, 63762 Grossostheim, Germany

T: +49 6026 503 296

ruthploch@maag.com

About Maag & Automatik Plastics Machinery

Maag is the worldwide leading manufacturer of gear pumps, pelletizing systems, and filtration systems for demanding applications in the plastics, chemical, petrochemical, and food industries. Maag develops, manufactures, and distributes innovative, customized solutions for complete pump and pelletizing systems – with the expertise based on its long-term industrial tradition since 1910.

Automatik Plastics Machinery has been manufacturing innovative pelletizing systems of the highest quality for several decades. It is the world leader in underwater strand pelletizing systems. That leadership position is founded on state-of-the-art technology and on comprehensive know-how in all pelletizing techniques and pellet forms. The company's longstanding tradition in development, production and global sales and distribution is complemented by comprehensive advice and service backup. Automatik Plastics Machinery is a subsidiary of Maag.

The whole company employs more than 500 staff at its headquarters in Switzerland and its production sites and sales offices in Germany, France, Italy, Singapore, Taiwan, Malaysia, China, Brazil, and the USA and is represented in the markets with its brands ”Maag Pump Systems“, ”Automatik Pelletizing Systems“, and ”Maag Filtration Systems“. Maag, a Dover Corporation Company (NYSE:DOV), is a part of the Pump Solutions Group, itself a business unit of Dover Engineered Systems.