StrainSmart® 9000 Dynamic Data Acquisition Software features post-processing data filtering.

Press Release Summary:

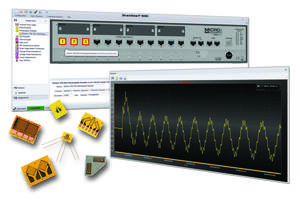

StrainSmart® 9000 Dynamic Data Acquisition Software allows user to sample up to 48 channels at speed up to 50,000 samples per second. Unit is used for real-time data recording, analysis, display and export. Product features one-touch autobalance and comes with turnkey Windows® based software platform. Software enables user to perform early error and omission pre-arm checks. StrainSmart® 9000 is suitable for experimental stress analysis and printed circuit board applications.

Original Press Release:

Micro-Measurements Introduces StrainSmart 9000 Data Acquisition Software

Simultaneous Recording and Analysis of Up to 48 Channels and 50,000 Samples Per Second with Fast, Easy Setup and Minimal-to-No Downtime

The Micro-Measurements® brand of Vishay Precision Group, Inc. (NYSE: VPG) (www.micro-measurements.com), industry experts in the design, development, and manufacture of resistive-foil sensors for high-precision strain and high-stress measurements, today announced the global market launch of its StrainSmart® 9000 dynamic data acquisition software. The software allows for the simultaneous sampling of up to 48 channels, at speeds of up to 50,000 samples per second, with fast, easy setup and minimal-to-no downtime.

Traditionally, the inherent complexities of dynamic test setups and programming, as well as repetitive manual measurement tasks, have created up to days, or weeks, of unwanted downtime. With StrainSmart 9000, it is now possible to perform accurate, real-time data recording, analysis, display and export within just minutes of software setup, with one-touch autobalance and post-processing data filtering. Designed for ease of use by students, engineers and scientists alike, StrainSmart 9000 offers an intuitive, complete turnkey Windows® based software platform for accurate, dynamic data acquisition, reduction, download, and display. The software easily translates end-user concepts into application-specific needs, with assured data accuracy through automatic error checking and calibration. A “verify” tool at setup allows the end-user to perform early error and omission pre-arm checks. Bridge excitation functions may be easily disabled for a complete pre-test noise evaluation scan. Visual representations provide instant access to hardware wiring and configuration validation data, with choice of either local or remote real-time display viewing.

Channel settings within StrainSmart 9000 are performed automatically from sensor properties, largely without manual intervention. Direct calculations of engineering units, including strain gage rosette principal and failure criteria stresses, along with input shunt calibration and user-defined assignments, are possible. Sensor-specific input assignments of strain gages, thermocouples, and other sensing types offer ease of mathematical data manipulation. Individual strain gage engineering data entry is also possible, with automatic error corrections for transverse sensitivity, Wheatstone bridge nonlinearity, and lead wire resistance. Parameters, such as thermal output, gage factor variation with temperature, and thermal coefficient of gage factor, are easily corrected via the assignment of a temperature sensor.

Unique signal visualization algorithms within StrainSmart 9000 provide in-depth insights, including full graphical representations of channel assignments, for reduced potential connection errors. Individual test setups and common parameters may be stored and saved by the end-user for later reuse. Larger data sets may be exported to multiple files automatically, as either ASCII text files, .csv files, or Microsoft® Excel documents.

StrainSmart 9000 is designed for seamless and direct compatibility with the Micro-Measurements System 9000 data acquisition system, as well as both Micro-Measurements and other industry strain gages (strain gauges), strain gage- based transducers, thermocouples, temperature sensors, high-level voltage sensors, and piezoelectric sensors. The software is now available as a no-charge upgrade for customers with legacy software versions. As it is site-licensed, StrainSmart 9000 may be installed on an unlimited number of PCs within the same facility or department. Typical applications include experimental stress analysis; electronics drop testing; printed circuit board (PCB) and finished product component reliability and subassembly testing; engine vibration monitoring; and fatigue life testing. The StrainSmart 9000 software system can further support virtually any dynamic data acquisition task, in which the simultaneous sampling of up to 48 channels, at speeds of up to 50,000 samples per second, is required. For more information on StrainSmart 9000, or other offerings from Micro-Measurements, visit www.micro-measurements.com.

About VPG

Vishay Precision Group, Inc. is an internationally recognized designer, manufacturer and marketer of: components based on its resistive foil technology; sensors; and sensor-based systems specializing in the growing markets of stress, force, weight, pressure, and current measurements. VPG is a market leader of foil technology products, providing ongoing technology innovations in precision foil resistors and foil strain gages, which are the foundation of the company’s force sensors products and its weighing and control systems. The product portfolio consists of a variety of well-established brand names recognized for precision and quality in the marketplace. To learn more, visit VPG at www.vpgsensors.com.

About Micro-Measurements®

Micro-Measurements, a Vishay Precision Group, Inc. (VPG) brand, is dedicated to the development, manufacture, and marketing of resistive-foil sensors for high-precision strain measurement. Micro-Measurements offers a full complement of strain gages, PhotoStress® equipment and coatings, data acquisition systems, and supplies necessary to obtain accurate, reliable stress data. Our products are used throughout the industrialized world — both in the practice of stress measurements analysis and as the sensing elements in a wide variety of transducers for measuring physical variables (weight, force, torque, pressure, etc.). More information about Micro-Measurements is available at www.micro-measurements.com.