Stationary Vise offers multiple part clamping.

Press Release Summary:

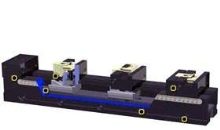

Available in 3 lengths, KONETEC KSM system consists of corrosion-resistant 65 or 90 mm wide clamping rail with vertical serration on inner side that allows jaws to be positioned with one hand. Based on wedge-hook principle, vise jaws are reversible and have smooth or serrated surface. Since no chips can jam rails, system is protected against damage and wear. Vise has mounting bores for assembly onto grid table and vertical grooves for mounting on machine tables.

Original Press Release:

Efficient Workholding with KONTEC KSM

SCHUNK Inc. has introduced a new workholding concept, the stationary clamping vice KONTEC KSM. Shorter lead times and increasing component variety require efficient workholding solutions. Consequently, the KONTEC KSM vice helps to increase efficiency in production considerably with its multiple partclamping features where several workpieces of the same size or even several different sized workpieces can be held at the same time.

This new, simple and quick system allows operators to reduce set-up costs tremendously. With the vertical serration on the inner side of the clamping rail, the jaw modules can be positioned quickly and accurately with one hand. To fix the jaws, just one screw has to be turned 180° - done. This unique concept is resistant to contamination - thus ensuring trouble-free clamping at any time.

The clamping method reduces vibrations and increases the workpiece stability during the machining process. Vise jaws, based on the wedge-hook principle, allow safe clamping of workpieces with ideal flow of forces. As a result, high precision even at high chip removal rates is guaranteed.

The clamping system consists of a corrosion resistant 65 or 90 mm wide clamping rail and is available in three standard lengths. The hard jaws, with smooth or serrated surfaces, are reversible and can be positioned via the vertical serration on the clamping rail. The vertical serration ensures a workpiece support on smooth surfaces. Since no chips can jam the rails, the system is protected against damage and wear and assures a high service life. The workpiece is pulled toward the clamping rail because the movable jaws use the pull-down effect. They are equipped with a gripping groove and a "click-in" interface that is used as a fixed surface for the next workpiece. A large variety of jaws are available. From top jaws without pull-down effect for a better workpiece support to special jaws, SCHUNK offers the right jaws for any application. The KONTEC KSM clamping device has mounting bores for easy assembly onto a grid table and vertical grooves for mounting on machine tables with T-nuts and is also a perfect complement for the SCHUNK UNILOCK system.

SCHUNK INC.

211 Kitty Hawk Drive

Morrisville, North Carolina 27560

Phone: 919.572.2705 or

800.772.4865

Fax: 919.572.2818

www.schunk-usa.com

info@schunk-usa.com