Spray System coats metallic and non-metallic substrates.

Press Release Summary:

Cold Gas Dynamic Spray (CGDS), based on thermal spray concepts, eliminates use of high temperatures. Materials are not melted in coating process. System applies powder coating materials such as aluminum, aluminum composites, copper, super alloys, silver, and titanium. System offers electrical conductivity, thermally conductive, and corrosion resistant properties. CGDS is suitable for metal joining and power generation products.

Cold Gas Dynamic Spray (CGDS), based on thermal spray concepts, eliminates use of high temperatures. Materials are not melted in coating process. System applies powder coating materials such as aluminum, aluminum composites, copper, super alloys, silver, and titanium. System offers electrical conductivity, thermally conductive, and corrosion resistant properties. CGDS is suitable for metal joining and power generation products.Original Press Release:

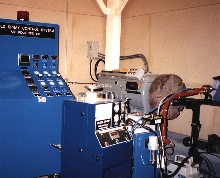

ASB Introduces New Cold Gas Dynamic Spray System For Metal Coating

Barberton, OH: ASB Industries, a leader in specialized metal coatings, has recently introduced a new coating technology, Cold Gas Dynamic Spray (CGDS).

Although based on thermal spray concepts, CGDS eliminates the use of high temperature and materials are not melted in the coating process. This eliminates phase changes or the formation of oxides and results in a very pure and dense coating layer.

The CGDS system is capable of applying a number of powder coating materials, including aluminum, aluminum composites, copper, super alloys, silver and titanium. These coatings can be applied to any metallic and many non-metallic substrates.

While the CGDS has many applications, it is especially suited to critical components in aerospace and defense, aerospace propulsion, metal joining, electrical conductivity. Thermal conductivity, corrosion resistance, and power generation products. It is also applicable for low temperature substrate repair on many industrial components or equipment.

For more information and system capabilities, contact ASB Industries, 1031 Lambert Street, Barberton, Ohio 44203-1689.

Tel: 330-753-8458. Fax: 330-753-7550. www.asbindustries.com.