Data and Database Management Software

Software provides mold balance analysis.

Press Release Summary:

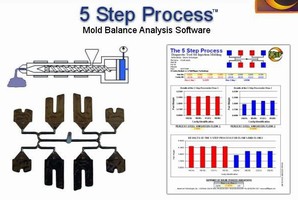

Incorporating graphics and multi-cavity mold configurations, 5 Step Process(TM) v1.2 helps moldmakers and processors isolate variations and quantify mold imbalances by root cause, typically shear-induced flow imbalances or steel variations in mold itself. Typical debugging takes hours, rather than days or weeks. Processors can use software at plant locations worldwide, giving injection molders ability to accommodate international installations.

Original Press Release:

Beaumont to Release New Version Of 5 Step Process(TM) Mold Balance Analysis Software

Adds Market-Driven Enhancements; Available At NPE; BTI Offers It Free to Injection Molders and Moldmakers for 30 Day Trial

ERIE, PA (April 17, 2006) - Injection molders and moldmakers seeking to debug and commission molds more quickly than ever before can now turn to the 4th generation of the 5 Step Process(TM) mold balance analysis and filling diagnostic software from Beaumont Technologies, Inc. (BTI). The software package is available for purchase on a single license for one installation or a site license with unlimited installations. Also potential buyers can try the software without commitment by requesting a 30 day free trial.

The new, more versatile, 1.2 version will be demonstrated by BTI at the NPE Booth #11224.

Because of the speed at which users can now analyze problems in molds using this approach, the software promises to pay for itself in the first or second application. Typical debugging only takes a few hours, not days or weeks, according to company officials. Cost for this latest generation software is $500 for a single license and $1,500 for a site license.

Additions to the upgraded 1.2 version of the software include:

o 4 additional, 4-cavity layouts,

o 2 additional, 8-cavity layouts,

o 1 additional, 12 cavity layout,

o 3 additional, 16-cavity layouts,

o 1 additional, 32-cavity layout,

o 1 additional, 64 cavity layout,

o a new and improved "look" and layout on computer screens,

o along with other internal program enhancements.

According to Dave Hoffman, BTI's Global Director, Technical Sales & Marketing, "Our highly successful 5 Step Process(TM) software, now being used in hundreds of injection molding operations worldwide, is constantly being updated, based on responses and needs of our customers and prospects. Thus, this 4th generation of our mold balance analysis software, incorporates new graphics and adds new multi-cavity mold configurations. Feedback from customers has been very positive regarding the ability to qualify molds faster and easier, and now, with 'new and improved' graphics and updated programming, the software is more user-friendly and easier to run than ever before."

The scientific approach of the 5 Step Process(TM) is superior over traditional mold balance analyses, which would provide only a percent imbalance and leave the user with no direction as to the root cause of the imbalance. The 5 Step Process(TM) helps moldmakers and processors isolate variations and quantify mold imbalances by their root cause, typically shear-induced flow imbalances or steel variations in the mold itself. The last generation enabled processors to expand and use the software at plant locations worldwide, giving injection molders the ability to accommodate international installations (i.e. transfer information, for example from U.S. codes to Mandarin codes and adding a validation process during export functionality, among others).

Beaumont Technologies, Inc., headquartered in Erie, PA, offers a unique mix of products designed to optimize the efficiencies of the mold, parts, and the injection molding process. These products and services are tools that help the injection molding industry become more competitive and profitable in world markets. The company's expertise lies within an in-depth understanding of polymer flow and processing technologies which enable molders and moldmakers to decrease lead-times while maintaining a high quality level of process and part control. Products include the patented MeltFlipper® melt rotation technology guaranteed to balance filling in hot and cold runner applications, the 5 Step Process(TM) mold commissioning software, CAE by BTI(TM) flow analysis services, and BTI Technical Seminars.

For more information on the new, 4th generation 5 Step Process(TM) mold debugging software, contact: Marketing Department, Beaumont Technologies, Inc., 2103 East 33rd Street, Erie, PA 16510-2529. Tel: (814) 899-6390. Fax: (814) 899-7117. E-mail: meltflipper@beaumontinc.com. Web www.beaumontinc.com.