Software provides engineering analysis of process data.

Press Release Summary:

Scorpion Software v7 helps maintain quality, consistency, and efficiency in thermal processes. Offered with graphic SPC function, it supports Scorpion datalogger. Software enables users to manage and analyze total process data on critical parameters, resulting in exact picture of complete oven or other thermal processes. It also allows multiple-user keyless access for data analysis, and lets users manipulate data displayed in 2D and 3D graphs.

Scorpion Software v7 helps maintain quality, consistency, and efficiency in thermal processes. Offered with graphic SPC function, it supports Scorpion datalogger. Software enables users to manage and analyze total process data on critical parameters, resulting in exact picture of complete oven or other thermal processes. It also allows multiple-user keyless access for data analysis, and lets users manipulate data displayed in 2D and 3D graphs.Original Press Release:

New SCORPION® Software Version-7 from Reading Thermal Systems Provides Engineering/QA Analysis of Key Process Data

Precise, flexible and user-friendly, newly upgraded Scorpion Software Version-7 from Reading Thermal Systems provides a range of useful tools to maintain quality, consistency and efficiency in thermal processes.

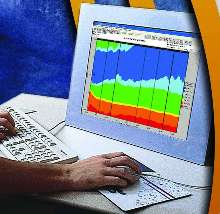

The software, featuring an improved graphic SPC function, supports Reading Thermal Systems' Scorpion datalogger. When run through a heating or cooling operation - on a conveyor, for instance - the Scorpion stores electronic signals from attached sensors that detect changes in the thermal environment. SV7 software enables users to manage and analyze total process data on critical parameters such as product level temperature, humidity, air velocity, heat flux and product core temperature.

The resulting exact picture of complete oven or other thermal processes, side to side and end to end, enables QA and Engineering Analysis supporting the preparation of in-spec product and maximum throughput in baking, food processing and other industries.

The software - Windows 98/NT/2000/XP compatible - allows multiple-user keyless access for data analysis. New toolbar buttons feature quick zoom and onscreen time, temperature and slope measurements; all-level users can easily manipulate data displayed in 2-D and 3-D graphs. A new Total Heat Graph displays total heat and heat type on product. The X-axis displays time, distance and percentage travel through the process (English or Metric), and the software includes an expanded, easy-to-use help section and an electronic manual.

To learn more, contact Richard Starke at Reading Thermal Systems, 380 Old West Penn Ave., Robesonia, PA 19551, phone 610-693-9547, fax 610-693-6262, email richard.starke@readingthermal.com.

About Reading Thermal Systems

Reading Thermal Systems is a leading provider of equipment and services for monitoring, analyzing and optimizing the efficiency and quality of thermal systems. Reading Thermal Systems delivers a comprehensive, integrated package of hardware, software and consulting services needed to produce best results from ovens, dryers and other high-volume thermal processes. To learn more, visit www.readingthermal.com.