Soft-Touch IP Panels Using MuCell® Process Are Finalist in SPE Automotive Innovation Awards

Daimler's Actros Truck Makes Unique Use of Microcellular Foam Technology

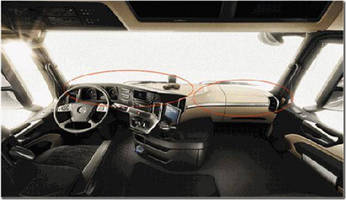

WILMINGTON, Mass.- Highly aesthetic soft-touch instrument panels for Daimler's Actros truck, which make innovative use of Trexel's MuCell® process, have been named a finalist in the body interior category of the Society of Automotive Engineers' (SPE) Automotive Innovation Awards competition. The 42nd annual Innovation Awards, regarded as the oldest and one of the most prestigious award competitions in the automotive and plastics industries, will be held Nov. 7 in Livonia, Mich.

Trexel's MuCell microcellular foam system is used to produce highly aesthetic soft-touch instrument panels for the Daimler Actros truck using Engel's innovative one-step Dolphin decompression/expansion process. The MuCell-equipped Dolphin method represents an economic alternative for the production of hard/soft components in comparison to other conventional multi-component and foaming methods.

"MuCell is an integral piece of an enabling technology to manufacture high-quality interior soft-touch parts," said Brent Strawbridge, Trexel's vice president of North American sales. Haptic and aesthetic results are excellent, resulting in a series of customized finishes including differentiated skins grains, a wide range of colors, and no joints. An important feature is that microcellular foaming helps to reduce total system cost by 30% to 40%. It is also more convenient and efficient compared to instrument panels made via solid injection molding.

In addition to improved economics, the MuCell-equipped injection molding process facilitates recyclability. The process produces no scrap and sprues can be recycled in the product (carrier) as an impact modifier.

In the two-shot molding system, a rigid support structure made of PC/ABS alloy is injection molded. After the mold rotates, the rigid structure is foamed in place with the MuCell process using a polyester-based thermoplastic elastomer (TPE). The highly integrated manufacturing method was developed in collaboration between Trexel, Engel, material supplier SO.F.TER Group, and mold maker Georg Kaufmann.

About Trexel and the MuCell® Process

The MuCell® Microcellular Foam technology from Trexel Inc. is a complete process and equipment technology that enables the production of high-quality plastic parts with significantly enhanced dimensional stability, lower weight/material, and reduced cycle time. MuCell® technology involves the introduction of precisely metered quantities of atmospheric gases (nitrogen or carbon dioxide) in the plasticizing unit of an injection molding machine to create a microcellular material structure in the end product. The creation of these microcellular structures brings a wide array of benefits including an increased part quality along with reduced production costs.

Trexel Inc. has led the development of the MuCell® Microcellular foaming technology and has pioneered many plastic processing solutions. Process deployment as well as equipment is supported by teams of highly qualified engineers through Trexel subsidiaries in North America, Europe, and Asia. For more information, visit www.trexel.com.

Press Contact:

Joseph Grande

413.684.2463

joe@jgrandecommunications.com