SMT 158HA Underfill from YINCAE Withstands Up to 400 Degree Celsius Temperature

Press Release Summary:

The SMT 158HA Underfill with zero outgassing is used for flip chip, wafer-level chip scale package application. The product is suitable for bare chip protection in packages such as memory cards, chip carriers, hybrid circuits and multi-chip modules. It can withstand up to 5x reflow.

Original Press Release:

YINCAE’s New Underfill with Zero Outgassing: SMT 158HA

(Albany, NY) September 4, 2018 YINCAE is excited to announce that we have developed an underfill with zero outgassing that is fully compatible with flux material, SMT 158HA.

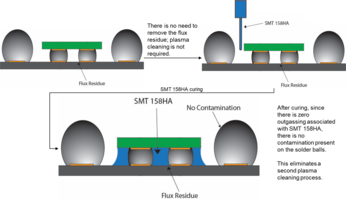

Due to its unique properties, SMT 158HA completely eliminates the cleaning process both after reflow and after curing. Zero outgassing means that there is no weight loss during curing therefore nearby solder balls and other components do not become contaminated. Also, the flux residue does not need to be removed before SMT 158HA is applied.

SMT 158HA was initially developed for high temperature applications, and can withstand temperatures of up to 400ºC. It also withstands up to 5x reflow.

This material can be used for flip chip, wafer-level chip scale package application. It is also suitable for bare chip protection in a variety of advanced packages such as memory cards, chip carriers, hybrid circuits and multi-chip modules. It is designed for high production and friendly environment where process speed and mechanical shock are key concerns.

For more information on YINCAE’s SMT 158HA underfill, or to learn more about the YINCAE product range, please email us at: info@yincae.com. You can also find more information by visiting our website at: www.yincae.com.

Founded in 2005 & headquartered in Albany, New York, YINCAE Advanced Materials is a leading manufacturer and supplier of high-performance coatings, adhesives and electronic materials used in the microchip & optoelectronic devices. YINCAE products provide new technologies to support manufacturing processes from wafer level, to package level, to board level and final devices while facilitating smarter and faster production and supporting green initiatives.