Smart Lift floats loads in assembly systems.

Share:

Press Release Summary:

Computer-controlled iLift(TM) lifting and balancing system for assembly and material handling lets operators apply 2 lb of physical force to move 150-lb load at speeds up to 4.9 ft/sec. Float mode allows direct movement of loads without need to push buttons from central control position, thus shaving seconds from cycle times. In-line slide handle eliminates vertical overtravel. Lift can be installed on existing and new rail configurations.

Computer-controlled iLift(TM) lifting and balancing system for assembly and material handling lets operators apply 2 lb of physical force to move 150-lb load at speeds up to 4.9 ft/sec. Float mode allows direct movement of loads without need to push buttons from central control position, thus shaving seconds from cycle times. In-line slide handle eliminates vertical overtravel. Lift can be installed on existing and new rail configurations.Original Press Release:

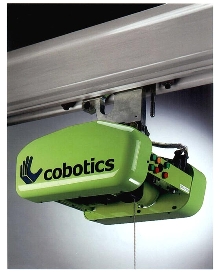

Cobotics' Intelligent iLift(TM) is The Most Advanced Lifting System Available For Assembly and Material Handling Applications

Cobotics' Intelligent iLift is The Most Advanced Lifting System Available For Assembly and Material Handling Applications

Evanston, IL - Cobotics, Inc. has introduced the iLift, the most advanced lifting and balancing system available for load movement in assembly and material handling environments. Featuring a highly sophisticated "float mode," vertical speeds up to 4.9 feet per second, and programmable automation, the iLift allows operators to meet their highest productivity goals, ensuring that the device will not be tied off to a column. Operators can manipulate loads in exceptionally fast cycle times, while applying just over 2 lbs. of physical force to move a 150-pound load.

The computer-controlled iLift, which is easily installed on existing and new rail configurations, offers operators a blend of power-assist and hands-on load positioning (using a patented float mode). The float mode allows direct movement of loads without the need to push buttons from the central control position-shaving seconds from cycle times. The responsive in-line slide handle also eliminates vertical overtravel for further productivity enhancement.

The iLift maximizes the functionality of end effectors through a programmable Hub, which features configurable 1/0 for controlling such end effector functions as air cylinders, interlocks, and proximity switches. The iLift also can be configured with Cobotics' iTrolley to create multi-axis Intelligent Assist Device (IAD) systems.

Cobotics, Inc. is the leading developer of Intelligent Assist Devices (IADs) for assembly and material handling applications. IADs are part of a class of devices called collaborative robots (cobots), which increase worker productivity, reduce cumulative trauma injuries, and error-proof tasks by enhancing human ability with intelligent motion control.