Skimmer provides by-pass clarification.

Share:

Press Release Summary:

Ruddy Duck oscillating skimming device works from 1/2 to 6 in. deep, and can remove 4 in. layer of contamination at rates up to 50 gpm. It can capture both top and stratified contamination layers. Powered by liquid hydraulics, its mouth drops well below surface regardless of skimming pump rate.

Ruddy Duck oscillating skimming device works from 1/2 to 6 in. deep, and can remove 4 in. layer of contamination at rates up to 50 gpm. It can capture both top and stratified contamination layers. Powered by liquid hydraulics, its mouth drops well below surface regardless of skimming pump rate. Original Press Release:

Ruddux Corp. Announces The Adaptation Of The Proven And Reliable RUDDY DUCK Skimmer to DEEP SKIMMING, From 1/2" to 6"

All recirculation systems generate contaminants that differ in Sp. Gr. from the parent fluid and become suspended (stratified) below the surface. For fixed weir skimmers to capture these; large volumes of liquid are required as well as large treating systems.

Fixed weir skimmers pass huge volumes of liquid, i.e. a 12" long weir skimming a 1/2" surface layer will pass approx. 17 GPM, a 1" layer approx. 35 GPM, a 2" layer, 98.5 GPM, and a 4" layer, approx. 269 GPM. This results in excessively large and costly equipment to remove very Small amounts of Contaminant.

A 12" weir RUDDY DUCK Skimmer will remove a 4" layer at 50 GPM.

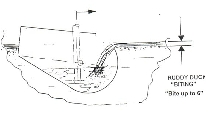

BY-PASS CLARIFICATION Featuring "DEEP SKIMMING"

Treating the full flow of process fluids for clarification (cleaning) can be very expensive and often unnecessary. Usually BY-PASS treatment is satisfactory at a fraction of the cost. The "Dilution" theory developed by Gage and Bidwell most often applies, thus only a portion of the fluid body need be treated on a by-pass basis. By properly sizing the by-pass stream and including an efficient and properly sized (clarifier) separator, acceptable clarity can be achieved while handling only a fraction of the total system volume. By-pass systems use smaller and less expensive equipment, less space, and lower operating costs than processing full flow.

The nature and concentration of the contaminant is important in selecting the size of the by-pass stream, the type and size of the clarification equipment and the draw off point to assure capture of the greatest concentration of contamination. The stream drawn off will contain both process fluid and contaminants to be delivered to the clarification equipment for processing. Good separation equipment will return clean fluid to the system and discard the contaminants.

Except under very turbulent conditions, heavy contamination will settle and should be drawn off the bottom or lower portion of the container. The light phase contamination will rise toward the top of the liquid container. This portion, (especially if it is a hydrocarbon) will normally consist of a top solid contaminant layer and a "rag" or "cream" phase layer(s) extending down into the process fluid. The longer the system is operated without clarification equipment, the deeper these phases will be.

These stratified phases are process fluid with scattered individual segments of contaminants. These are so small that surface tension prevents them from rising or their specific gravity approximates that of the process fluid (normally around 1.0 for an aqueous solution). The rag or cream phases are just as detrimental to the process as the top solid layer and consist of the same components. If allowed to remain these stratified contaminants will affect the product/process quality and the life of the process fluid. Fixed weir skimmers take a thin surface layer of contamination/coolant, leaving the lower stratified contaminant. Oleophillic skimmers (belt, tube, rope, and disc) capture mostly parent fluid as it cannot capture the non-continuous contamination in the stratified phase.

The By-pass DEEP SKIMMING technique can be used to capture both top and stratified contamination layers. The RUDDY DUCK Skimmer, the only oscillating skimming device, powered by liquid hydraulics, consistently takes a "bite" of the liquid. Its mouth drops well below the surface (1/2" for the smallest model) regardless of the skimming pump rate. Special models can take "bites" of several inches of liquid surface, depending upon the nature of the contamination. ONLY with DEEP SKIMMING can the "rag" or "cream" phases be captured for treatment. Only if the "rag" or "cream" phases are treated can the life of the process fluid be greatly extended.