SiP Test, Production Alignment System combines speed, precision.

Press Release Summary:

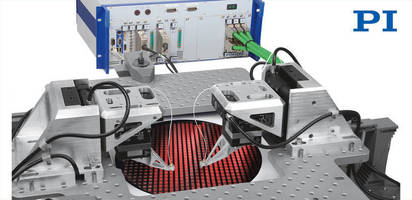

Combining advantages of piezoelectric on servo-motorized drives, FMPA Fast Multichannel Photonics Alignment Engine addresses need for fast, parallel, nanoscale-accurate, multi-degree-of-freedom global optical alignment optimization required in key SiP production steps from planar test to packaging. System is based on digital motion controller with embedded advanced alignment and tracking functionality and hybrid precision scanning and tracking mechanism.

Original Press Release:

SiP Test & Production Alignment Engine from PI - 2016 R&D 100 Award Finalist

A solution is now available for fast, parallel, nanoscale-accurate, multi-degree-of-freedom global optical alignment optimization required in key SiP production steps from planar test to packaging.

Auburn, MA –The FMPA Fast Multichannel Photonics Alignment Engine is an advanced alignment system based on a highly specialized digital motion controller with embedded advanced alignment and tracking functionality and a hybrid precision scanning and tracking mechanism combining the advantages of piezoelectric on servo-motorized drives. From motion control and nanopositioning solutions expert PI (Physik Instrumente) LP, the FMPA system is a 2016 R&D 100 Awards Finalist, which honors the most innovative technologies. Now in its 54th year, often referred to as the “Oscars of Invention”, winners of this prestigious award will be announced on November 3rd, during the R&D 100 conference, at the black tie gala dinner.

The Silicon Photonics (SiP) Problem

The convergence of silicon based electronics and photonics promises a leap in data throughput, parallelism, and energy efficiency. Design and materials challenges have by now been addressed. Practicalities of testing and packaging have not.

Test and packaging of silicon photonics elements require nanoscale alignments that cannot be performed using visual or mechanical references. Instead, these optimizations must enhance the optical throughput itself. In addition, SiP designs often incorporate multiple parallel optical paths with multiple, interacting inputs and outputs, all needing optimization. Simple economics, as well as optical realities, dictate that these be optimized simultaneously, yet until now there has been no technology capable of doing this.

Watch the FMPA System Animation

https://www.youtube.com/embed/Skdf8ekrHbU?rel=0

The Solution

With more than three decades of experience in ultra-precision motion control for semiconductor manufacturing and metrology, PI has addressed the need for fast, parallel, nanoscale-accurate, multi-degree-of-freedom global optical alignment optimization required in key SiP production steps from planar test to packaging.

This enabling solution integrates PI’s high-throughput piezo nanopositioning technologies and ultraprecision motion control with novel algorithms. Introduced at the SPIE Photonics West 2015 conference, the groundbreaking technology was developed by PI’s team that comprises more than a century of photonics alignment automation experience and includes foundational participants in the field. The system is part of PI’s broad offering of photonics alignment engines ranging from software-driven stage solutions to integrated 6-axis hexapod micro-robots with built-in alignment functionality.

Specifications, Datasheet, More Information

http://www.pi-usa.us/products/Photonics_Alignment_Solutions/index.php#FMPA

Standard and Custom

PI has over 4 decades of experience providing in-house engineered precision motion control solutions, and can quickly modify existing product designs or provide a fully customized OEM part to fit the exact requirements of the customer’s application.

USA / Canada

http://www.pi-usa.us | info@pi-usa.us

East

(508) 832-3456

Midwest

(508) 832-3456

WestÂ

(949) 679-9191 (LA Area & Mexico)

(408) 533-0973 (Silicon Valley/Bay Area)

About PI

PI is a leading manufacturer of precision motion control equipment, piezo motors, air bearing stages and hexapod parallel-kinematics for semiconductor applications, photonics, bio-nano-technology and medical engineering. PI has been developing and manufacturing standard & custom precision products with piezoceramic and electromagnetic drives for 4 decades. The company has been ISO 9001 certified since 1994 and provides innovative, high-quality solutions for OEM and research. PI is present worldwide with twelve subsidiaries, R&D / engineering on 3 continents and total staff of 850+.

> READ the PI Blog

> WATCH PI Videos on YouTube

> FOLLOW PI on Twitter