Simulation Software facilitates 3D injection molding.

Press Release Summary:

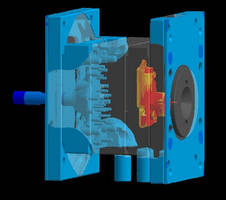

By consistently using Finite Volume Method with its 3D approach, SIGMASOFT® enables user to account for all relevant influencing factors in injection molding process, including part, mold, hot runner, and process management. Simulation model obtained is integrated into network automatically and with no finishing work required. Generated simulation model is then used to conduct thermal mold analyses, which serve as basis for component-related mold optimization and minimization of cycle times.

Original Press Release:

Injection Molding Simulation: This is the Time for a New Generation

By consistently using the "Finite Volume Method" with its 3D approach, SIGMASOFT® enables the user to account for all relevant influencing factors (part, mold, hot runner, process management) in the injection molding simulation, significantly expanding the possibilities of conventional analysis software. The benefits included in this approach comprise improved accuracy and predictability, as well as a considerably enhanced range of applications for injection molding simulation: design of part and mold, mold development, identification of process windows and process troubleshooting.

Schaumburg, Illinois- Sigma Plastic Services presented its SIGMASOFT® software designed for 3D injection molding simulation at the recent Euromold 2011. SIGMASOFT® offers a variety of functions unmatched by conventional simulation software, while enabling the user to obtain a profound understanding of the causalities, considering not only part defects, but also concerning mold performance, energy efficiency and achievable process windows.

When developing parts to be produced by injection molding, designers typically use simulation programs that calculate mold filling, the phases of post-pressure and cooling, including de-molding, as well as the warpage in the plastic part. This is done on the basis of empirical data and mathematical models. There is no doubt, however, that a program's predictions can be precise if it considers not only the component geometry, but if it moreover physically and exactly determines all relevant influencing factors (e.g. components and materials of the mold, concept and media of tempering, hot runner and actual process management), and appropriately integrates them all into the calculations.

While consistently and exclusively using 3D technology, SIGMASOFT® meets all these requirements. SIGMASOFT® has always applied 3D technology only, in its functionality. The software is thus based on the highest possible level of experience in the area of 3D injection molding simulation and this is why users feel safe and confident using it today.

Because it employs the "Finite Volume Method," SIGMASOFT® enables fast and easy integration of all available influencing factors relevant to geometry and process, with minimum interaction required from the software user at any point in time during the process of product development. The simulation model obtained is integrated into a network automatically and with no finishing work required, a unique feature of SIGMASOFT® which also drives a considerable increase in productivity for the user. The generated simulation model is then used to conduct thermal mold analyses, which serve as a basis for component-related mold optimization and minimization of cycle times. Moreover, the model enables the user to make detailed statements concerning the efficiency of the employed tempering concept from the energy-consumption side. In addition, ejector forces during de-molding can be determined and subsequent thermal treatments on the mechanical components of the press (for instance polishing or galvanization) can be analyzed for their effects on stress distribution and dimensional stability.

During Euromold, Dr.-Ing. Götz Hartmann, managing director of SIGMA Engineering GmbH in Aachen, Germany explained these features of SIGMASOFT® in a lecture he gave as part of the "strategies and trends in mold manufacturing" series of lectures that the SKZ (Süddeutsches Kunststoffzentrum) organized in tandem with Euromold. The title of Dr. Hartmann's lecture was "Design & Process - integrated 3D simulation of polymer injection molding processes - The new generation of injection molding simulation." The lecture was given by Dr. Hartmann on November 30, 2011.

SIGMA (www.sigmasoft.de) is 100% owned by MAGMA (www.magmasoft.de), market leader in casting simulation technology based in Aachen, Germany. Our SIGMASOFT® simulation solution optimizes the development process for plastics components and injection molds, as well as the management of injection molding processes. The two product lines - plastics injection molding and metal casting - share the same 3D simulation technologies focused on the optimization of design and process. SIGMASOFT® thus includes a variety of process-specific models and 3D simulation methods developed, validated and constantly improved over a period of 25 years for the area of metal casting. A design- and process-oriented simulation tool, SIGMASOFT®, with its enhanced simulation approach, means a significant benefit to users, if compared to any other conventional simulation approach employed in plastics injection molding.

Success in injection molding simulations requires a direct exchange between simulation users, with requirements originated from their practical experience, and a support team competent in the plastics field, as well as with an application-oriented team of designers. To provide for this, SIGMA Engineering GmbH offers direct marketing and support, with an application-oriented team of designers located at their Aachen site and well-established development partners in Europe.