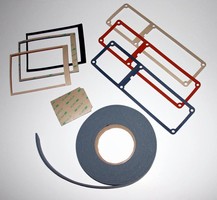

Silicone Gaskets and Pads with High Performance Acrylic Adhesive Backings

April 9, 2008

Stockwell Elastomerics announces the availability of Silicone Foam and Closed Cell Silicone Sponge Enclosure Gaskets and Cushioning Pads with high strength pressure sensitive acrylic adhesives for bonding to powder coated metal surfaces and certain low surface energy plastics.

Secure lamination of acrylic pressure sensitive adhesives onto silicone rubber is not possible without priming the silicone rubber. Stockwell has developed primers that allow for lamination of 3M Corporations' 9485 acrylic transfer film adhesive and 9490LE film supported acrylic adhesive onto silicone foam, closed cell silicone sponge and solid silicone rubber. Gaskets are then water jet cut or die cut to size, or slit-to-width into rolls for installation.

3M 9485 acrylic adhesive is .005" thick unsupported transfer film adhesive. Its ultimate bonding strength on stainless steel is 150 lb/inch of width. 9485 withstands high temperature excursions for brief periods up to 400°F, and long term temperatures up to 300°F continuous without slumping or shearing. This adhesive is well suited for thick silicone sponge gaskets on most metal surfaces. Unsupported transfer film adhesives allow for bonding to contoured surfaces and permit forming corner radii using strips of gasketing.

3M 9490LE acrylic adhesive is .0067" thick film supported adhesive. This adhesive is formulated for secure bonding to most surfaces, including many low surface energy plastics and powder coated metal surfaces. 9490LE withstands high temperature excursions for brief periods up to 300°F, and long term temperatures up to 200°F.

Film supported adhesive backings provide dimensional stability, which may benefit the

assembly of thin-walled gaskets onto some enclosure designs.

Silicone Foams and Closed Cell Silicone Sponge materials are available from .032" thick to .500" thick in soft, medium and firm densities. Stockwell inventories the complete line of Rogers Bisco(TM) Silicone foam and St. Gobain's Cohrlastic® closed cell silicone sponge.

Stockwell Elastomerics' core competence is the fabrication and molding of silicone rubber and similar high performance elastomers. Their in-house capabilities include custom molding, die cutting, adhesive lamination and water jet cutting. Many of Stockwell's customers take advantage of water jet cutting for fast turn prototypes and initial production.

For sample swatches of .062" thick closed cell silicone sponge with 9485 and .125" thick silicone foam with 9490LE high performance acrylic adhesives contact Stockwell Elastomerics directly.

For complete information on Stockwell Elastomerics' offerings in silicone rubber products, and molding and fabrication capabilities contact:

Stockwell Elastomerics, Inc.

4749 Tolbut Street

Philadelphia, PA 19136

(215) 335-3005

Email: service@stockwell.com

or wbstockwell@stockwell.com

Contact Name: William B Stockwell

Title: President

E-mail: wbstockwell@stockwell.com