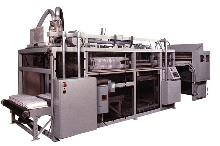

Sheet Stacker cuts, conveys and accumulates.

Press Release Summary:

High Speed Rotary Sheeter/Stacker processes rolls of material into sheets at up to 1,000 ft/min. Sheeter portion has rotary single-knife fixed-bed cutter. Sheets are conveyed on vacuum conveyor to point where material is knocked off belt onto stacker. When stack is full it automatically lowers for off-loading, while secondary finger-tray keeps collecting sheets. When off-loading is complete, stack raises back up, and collects sheets in finger-tray.

High Speed Rotary Sheeter/Stacker processes rolls of material into sheets at up to 1,000 ft/min. Sheeter portion has rotary single-knife fixed-bed cutter. Sheets are conveyed on vacuum conveyor to point where material is knocked off belt onto stacker. When stack is full it automatically lowers for off-loading, while secondary finger-tray keeps collecting sheets. When off-loading is complete, stack raises back up, and collects sheets in finger-tray.Original Press Release:

CONTECH Introduces New High Speed Rotary Sheeter/Stacker

CONTECH's new High Speed Rotary Sheeter/Stacker is designed for continuous 24 hours a day, seven days a week operation. The new rotary sheeter/stacker is capable of processing rolls of material into sheets at a rate up to 1,000 ft/min depending on the material. The sheeter portion uses a rotary single-knife fixed-bed cutter, which is not only fast but extremely accurate. The sheets are conveyed on a vacuum conveyor to the point where the material is knocked off the belt onto the stacker. (Equipment shown processes oil absorbent material, other materials would require different style of stacker) When the stack is full it automatically lowers for off-loading, meanwhile a secondary finger-tray keeps collecting sheets. When off-loading is complete the stack raises back up, collects the sheets in the finger-tray, and continues collecting sheets from the sheeter.

CONTECH's custom Automation Engineering capability allows them to design, engineer, and build rotary sheeter/stacker systems to customer's exact specifications, making them completely compatible with existing plant equipment. CONTECH manufactures a complete line of material processing equipment including die cutters, slitters, rewinders, applicators and more.