Sealed SFP Assemblies help maximize PCB real estate.

Press Release Summary:

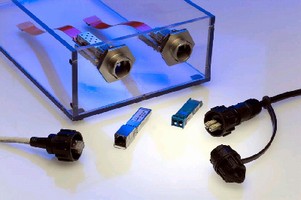

Panel-mounted Sealed SFP Assemblies accommodate SFP transceivers and enable transceiver to be removed or replaced from either side. They also enable upgrades from copper Ethernet system to optical transceiver. Receptacles feature IP67-rated hardened user interface for dust and water protection. Made of diecast, units have electronically conductive sealing gaskets that deliver EMI suppression and are compatible with ODVA compliant optical and copper assemblies.

Original Press Release:

Molex Expands Industrial Product Line To Include Sealed SFP Assemblies

LISLE, Ill. - March 27, 2007 - Molex (NASDAQ: MOLX and MOLXA) has introduced the Sealed SFP Assemblies in response to customer requests to have the ability to incorporate SFP transceivers into sealed panel mounted receptacles. These new solutions also meet a market need for upgrades from a copper Ethernet system to an optical transceiver, or can interchange between the two as requirements demand. In addition to being versatile, they also eliminate the need to replace receptacles or change the board configuration. By incorporating the SFP Transceiver into a wall mounted receptacle, these new assemblies enable it to be removed or replaced from either side of the receptacle, making factory installations and field upgrades easier.

The Sealed SFP Assemblies are designed to maximize valuable PCB real estate, while providing an environmentally-sound interface. They feature an IP67-rated hardened user interface for dust and water protection. Additionally, their durable diecast receptacles have electronically conductive sealing gaskets that deliver EMI suppression in a rugged housing. Created to withstand harsh environments, these optical and electrical-integrated connector systems are well-suited for WiFi and WiMax wireless base station and antenna feed applications; industrial applications such as system controls, monitoring and data routers; and telecommunication applications, including outdoor environment data routers, switches or networking equipment and FTTx connections. They can also be used for mobile communications equipment such as military and broadcast, as well as with BPL (Broadband over power lines), food processing and rugged test equipment.

"The industrial, mobile and military markets are constantly seeking ways to reduce PCB real estate and enclosure size with compact, yet environmentally-rugged interconnect solutions," said Dave Rifkin, product manager, Molex. "By adding the Sealed SFP Assemblies to our existing product line, Molex can meet customer needs for connector systems that fit into tight spaces and withstand harsh operating conditions."

Compatible with ODVA compliant optical and copper assemblies, the Sealed SFP Assemblies accommodate industry standard connectors and cable assemblies to enable future upgrades or backward compatibility. Additionally, the SFP device can be installed or removed from the front or back side of the receptacle, which makes it easy to undergo factory installations and field upgrades.

The Sealed SFP Assemblies are available at an affordable cost, starting at $61.00 in quantities of 500 pieces. Lead-time is four weeks for initial orders. For further information, visit the Molex website at: www.molex.com/product/fiber/indsfp.html.

About Molex

Molex is a 68-year-old global manufacturer of electronic, electrical and fiber optic interconnection systems. Based in Lisle, Illinois, USA, the company operates 58 manufacturing facilities in 19 countries. The Molex website is www.molex.com.

Molex® is a Registered Trademark

David Rifkin

Product Marketing Manager

Molex

630-512-8797

david.rifkin@molex.com