Schaeffler Plant Produces One-Millionth Ball Screw Drive for Electromechanical Steering Systems

Precision bearings and automotive components supplier The Schaeffler Group has reached an important milestone after the Company produced its one-millionth ball screw drive for electromechanical steering systems.

A ceremony took place recently to celebrate the one-millionth ball screw drive to leave Schaeffler's fully automated production plant in Herzogenaurach, Germany. Attending the ceremony were Maria-Elisabeth Schaeffler (Owner), Dr. Peter Pleus (President Schaeffler Group Automotive), Dr. Christoph LÖffel (Head of the Ball Screw Drive Product Line) and Peter Wirkner, Plant Manager at Herzogenaurach.

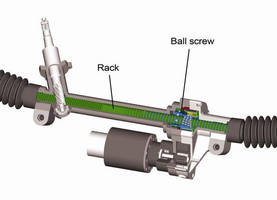

Manufactured at the Herzogenaurach plant since 2007, Schaeffler's energy efficient ball screw drive is being utilised on the electromechanical steering system for the Volkswagen Tiguan. Schaeffler supplies the ball screw drive to Volkswagen, as well as a toothed rack, which is partly designed as a spindle on which the drive is located. Ball screw drives are used to transform rotary motion into linear motion through a direct coupling between the drive element and the output element. In the Tiguan, the ball nut is driven by a servomotor, which is linked to the ball screw drive via a belt.

These low friction, low noise ball screw drives play an important role in helping to improve a vehicle's fuel consumption and reduce CO2 emissions. As well as offering the driver optimised handling, the latest electromechanical steering systems can also reduce fuel consumption by as much as 3% compared to conventional hydraulic steering systems.

A key advantage of an electromechanical steering system over a hydraulic one is that the servomotors require energy only when specific steering manoeuvres are carried out, whilst hydraulic pumps need to maintain hydraulic pressure at all times, therefore demanding more energy. This means that pumps and feeds are no longer required on an electromechanical system, which reduces the space required for operating the steering system.

Other customers of Schaeffler's first one million ball screw drives include automotive supplier TRW. The ball screw drives are not only used in Europe, but also on vehicles manufactured in the US by Volkswagen, Ford and BMW. The aerospace sector is another major user of high precision ball screw drives, which are often found in an aircraft's tail steering system.

As Maria-Elisabeth Schaeffler commented: "Reaching one million ball screw drives is an incentive to be committed to keeping up the good work." For 2010, Schaeffler has already secured orders for 1.2 million ball screw drive units. Orders for 2011 and 2012 amount to 1.9 million and 2.3 million units respectively.

"We are one of the leading innovators in this industry and we will continue to do all we can to convince our customers through our innovative capacity and quality," said Dr. Christoph Löffel, Head of the Ball Screw Drives Product Line at Schaeffler.

For more information on Schaeffler's range of high precision ball screw drives, please visit www.schaeffler.co.uk or telephone the marketing department on 0121 313 5870 or email info.uk@schaeffler.com

Dean Palmer

Director

SilverBullet PR Ltd

Tel: 01780 753 000

Mobile: 07703 023 771

Email: dean@silverbulletpr.co.uk

www.silverbulletpr.co.uk

Schaeffler (UK) Ltd,

Forge Lane

Minworth

Sutton Coldfield

West Midlands B76 1AP

Tel: 0121 351 3833

Fax: 0121 351 7686

e-mail: info.uk@schaeffler.com

www.schaeffler.co.uk