Sandvik Coromant to Release Two New Grades for Interrupted Hard-part Turning Operations

Press Release Summary:

Sandvik Coromant will have two new grades for interrupted hard-part turning operations available in October of 2018; CB7125 and CB7135. They will complete and complement the existing CB7105 and CB7115 grades. These grades enable the performance of medium-to-heavy interrupted cuts and removal of the hardened layer in steel components for the automotive industry. They offer longer and more consistent tool life and improved surface finish and dimensional tolerances. Both grades are optimized for turning steel materials with a hardness of 58-62 HRC. CB7125 features a new PVD coating that improves wear and fracture resistance. CB7135 features a high CBN content with high fracture resistance and predictable machining results. Both grades come in positive and negative basic shapes with multiple edge preparations and are suitable for continuous or continuous-to-light interrupted cutting applications.

Original Press Release:

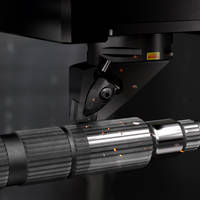

Top Grades for Hard-part Turning

Sandvik Coromant now has a complete offer for hard turning operations

Cutting tool and tooling system specialist, Sandvik Coromant, is set to release two new grades for interrupted hard-part turning operations: CB7125 and CB7135. Available in October 2018, the grades will complete the company’s offer for hard-part turning, complementing the existing CB7105 and CB7115 grades.

The latest Sandvik Coromant grades enable the performance of medium-to-heavy interrupted cuts and removal of the hardened layer (depth of cut up to 2 mm) in case- and induction-hardened steel components, typically for the automotive industry. For these applications, CB7125 and CB7135 offer longer and more consistent tool life, good levels of surface finish and consistent dimensional tolerances.

“For everyone working with transmission and other hard-turned components, there is a reason to choose these CBN grades,” explains Torbjörn Ågren, Product Manager-General Turning at Sandvik Coromant. “Not least because adding value in speed capabilities and providing a more secure edge line and consistent tool life means lower cost per component. This is particularly the case when aiming for a one-cut strategy, namely a single cut with larger chip thickness, at high speed.”

CB7125 and CB7135 are optimized for turning steel materials with a hardness of 58–62 HRC. Designed for medium intermittent cutting, CB7125 features a new PVD coating that provides improved wear and fracture resistance for extended tool life. This grade, which contains medium CBN content, is ideal for turning shaft splines and shafts with chamfered oil holes or pockets. Further applications include gear facing, the hard-to-soft turning of crown wheels, and the removal of hardened layers.

The CB7135 grade is pitched at the efficient longitudinal turning of gears and shafts with unchamfered keyways or pockets, as well as CV joint components such as the inner/outer race and cage. Featuring a high CBN content, the grade offers high fracture resistance and predictable machining results.

Available for T-Max® P, CoroTurn® 107 and CoroTurn® TR tooling systems, the new grades come in both positive and negative basic shapes, with various edge preparations. Cutting data recommendations for CB7125 include a cutting speed of 100–200 m/min (328–656 ft/min) and feed rate of 0.05–0.45 mm/rev (0.002–0.018 in/rev), while for CB7135 a cutting speed of 80–160 m/min (262–525 ft/min) and feed rate of 0.05–0.4 mm/rev (0.002–0.016 in/rev) should be achievable, depending on the specific application.

With the introduction of CB7125 and CB7135, Sandvik Coromant now offers a complete hard-part turning solution, along with the existing and complementary CB7105 and CB7115 grades, which are suitable for continuous or continuous-to-light interrupted cutting operations.

Sandvik Coromant

Part of global industrial engineering group Sandvik, Sandvik Coromant is at the forefront of manufacturing tools, machining solutions and knowledge that drive industry standards and innovations demanded by the metalworking industry now and into the next industrial era. Educational support, extensive R&D investment and strong customer partnerships ensure the development of machining technologies that change, lead and drive the future of manufacturing. Sandvik Coromant owns over 3100 patents worldwide, employs over 7,900 staff, and is represented in 150 countries.

For more information visit www.sandvik.coromant.com

Follow us on social media:

Facebook | YouTube | Twitter | LinkedIn | Instagram

Contact details for editorial inquiries

Contact: Angela Roxas, PR & Sponsorships – Sandvik Coromant

Phone: (201) 294-9160

Email: angela.roxas@sandvik.com